In the rapidly evolving world of automotive manufacturing, the significance of Automotive Metal Stamping Parts remains paramount. As we look towards 2025, industry experts are predicting transformative trends that will shape this sector. According to Dr. Emily Carter, a leading specialist in automotive engineering, "The next wave of innovation in automotive metal stamping will not only enhance efficiency but also contribute significantly to sustainability efforts across the industry." This insight sheds light on the growing emphasis on incorporating advanced technologies and eco-friendly practices in metal stamping processes.

As automakers strive to meet increasing consumer demands and stringent environmental regulations, the importance of understanding key trends in Automotive Metal Stamping Parts becomes essential. The integration of automation, improved material technologies, and innovative design methodologies is set to redefine how these parts are produced. Through this exploration, we will delve into the most impactful trends influencing the landscape of automotive metal stamping, equipping stakeholders with the knowledge necessary to navigate this dynamic sector effectively. As we prepare for the advancements that 2025 holds, it is clear that staying informed about these trends will be crucial for maintaining a competitive edge in the automotive industry.

The automotive metal stamping industry is on the brink of a technological renaissance as we approach 2025. Emerging technologies are reshaping the landscape of metal stamping, offering increased efficiency and precision in manufacturing processes. Advanced automation, driven by robotics and artificial intelligence, is streamlining production lines, reducing human error, and enhancing the quality of stamped components. These innovations not only optimize operational efficiency but also contribute significantly to cost reduction, allowing manufacturers to stay competitive in a fast-evolving market.

Furthermore, the integration of smart technologies and IoT (Internet of Things) is revolutionizing how metal stamping operations are monitored and managed. Real-time data analytics enable manufacturers to predict maintenance needs, thereby minimizing downtime and maximizing productivity. Additionally, the adoption of additive manufacturing techniques alongside traditional stamping methods is creating new possibilities for design flexibility and material optimization. By 2025, these technological advancements are expected to redefine the capabilities of automotive metal stamping parts, ensuring they are lighter, stronger, and more suited to meet the demanding requirements of the automotive industry.

As the automotive industry continues to evolve, sustainability practices are becoming integral to the production of metal stamping components. Manufacturers are increasingly adopting eco-friendly processes designed to minimize waste, reduce energy consumption, and utilize recyclable materials. This shift not only contributes to environmental preservation but also meets the growing consumer demand for greener vehicles, fostering a culture of innovation within the industry.

One of the key trends shaping sustainability in metal stamping is the implementation of advanced technologies such as automation and artificial intelligence. These innovations streamline production processes, enhance precision, and optimize resource management. Additionally, the focus on sustainable sourcing of raw materials and the development of lightweight metal alloys are influencing the design and functionality of components, leading to vehicles that are not only more efficient but also have a smaller carbon footprint. By integrating these sustainable practices, automotive manufacturers are setting a precedent for responsible production while meeting stringent environmental regulations.

| Trend | Description | Impact on Sustainability | Implementation Challenges |

|---|---|---|---|

| Increased Use of Recycled Materials | Utilizing recycled metals in the manufacturing process to reduce waste. | Decreases environmental footprint and resource consumption. | Quality control and supply chain consistency. |

| Advanced Manufacturing Technologies | Adoption of technologies such as automation and AI in metal stamping. | Enhances precision and reduces material waste. | High initial investment and need for skilled labor. |

| Energy Efficiency Improvements | Implementing energy-saving measures in production processes. | Reduces carbon emissions and operational costs. | Need for ongoing monitoring and upgrading of equipment. |

| Innovative Design for Reusability | Designing stamping parts that can be reused or repurposed. | Minimizes waste and maximizes lifecycle of components. | Requires collaboration across design and engineering teams. |

| Sustainable Sourcing Practices | Ensuring materials are sourced sustainably and ethically. | Supports responsible mining and fair trade practices. | Complex supply chain management and verification of sources. |

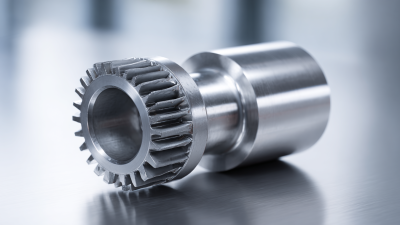

As the automotive industry continues to evolve, the adoption of lightweight materials is transforming the landscape of metal stamping processes. These materials, such as aluminum and advanced high-strength steel, play a crucial role in reducing vehicle weight, which in turn enhances fuel efficiency and overall performance. The lighter the vehicle, the less energy required for movement, making lightweight materials not just a trend but a vital component of modern automotive design.

The integration of these materials into stamping processes poses unique challenges and opportunities. Automotive manufacturers must adapt their techniques to accommodate the different physical properties of lightweight metals, which can behave differently under stress and during the stamping process compared to traditional steel. This transition requires a re-evaluation of tooling, die design, and process parameters to ensure precision and quality while maintaining production efficiency. Furthermore, innovations in stamping technology, such as progressive die stamping and hydroforming, are becoming increasingly important in enabling manufacturers to work with these materials effectively and maintain competitive advantage in the market.

The integration of automation and robotics into metal stamping operations is revolutionizing the automotive industry. These technologies enhance production efficiency, reduce labor costs, and improve product quality. With the ability to perform repetitive tasks with precision, robots can streamline processes such as loading and unloading materials, die changes, and quality inspections. This not only accelerates the manufacturing cycle but also minimizes the likelihood of human error, resulting in more consistent outputs.

Additionally, the implementation of advanced robotics allows for greater flexibility in production. Manufacturers can easily reprogram robotic systems to accommodate different tasks or adjust to varying production volumes without significant downtime. This adaptability is particularly beneficial in an era where customization and rapid prototyping are increasingly in demand. Furthermore, automated systems can gather and analyze data in real-time, providing valuable insights into operational efficiency and enabling preemptive maintenance, thereby reducing the risk of costly production halts. As the automotive sector continues to evolve, the reliance on automation and robotics in metal stamping will undoubtedly shape the future of manufacturing practices.

The automotive metal stamping industry is witnessing significant transformation, driven by evolving consumer demands and advancements in manufacturing technologies. According to a recent report by Grand View Research, the global automotive metal stamping market was valued at approximately USD 25 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of around 5.5% through 2030. This growth is largely fueled by the increasing production of electric vehicles (EVs) and the need for lightweight materials to enhance fuel efficiency and reduce emissions.

Key players in the industry are adapting to these trends by investing in innovative stamping technologies such as progressive dies and servo presses, which provide higher precision and efficiency. A report from MarketsandMarkets highlights that advancements in automation and robotics are also reshaping manufacturing processes, enabling faster turnaround times and reduced labor costs. Furthermore, the increasing adoption of advanced high-strength steels (AHSS) and aluminum is expected to play a crucial role in the production of automotive components, further fueling market growth. As the automotive sector continues to evolve, staying informed about these trends and technologies will be essential for industry stakeholders.