In the realm of modern industrial applications, the use of Galvanized Gasket has gained significant attention due to its superior durability and performance benefits. According to a recent report by MarketsandMarkets, the global gasket market is expected to reach $16.3 billion by 2026, with galvanized materials playing a crucial role in this growth due to their resistance to corrosion and ability to withstand extreme temperatures. Galvanized Gaskets are increasingly favored in sectors such as oil and gas, chemical processing, and renewable energy, where reliability and longevity are paramount. By preventing leaks and ensuring optimal sealing under varying conditions, these gaskets contribute not only to efficiency but also to safety in industrial operations. As industries continue to evolve, the adoption of advanced materials like Galvanized Gasket signifies a shift towards more sustainable and resilient manufacturing practices.

Galvanized gaskets, known for their corrosion resistance and durability, are a vital component in numerous industrial applications. Composed primarily of steel that has been coated with a layer of zinc, these gaskets offer enhanced protection against oxidation and rust. The galvanization process not only improves the lifespan of the gasket but also maintains its mechanical integrity under varying temperature and pressure conditions. As a result, galvanized gaskets are particularly beneficial in environments that are prone to moisture and chemical exposure.

Galvanized gaskets, known for their corrosion resistance and durability, are a vital component in numerous industrial applications. Composed primarily of steel that has been coated with a layer of zinc, these gaskets offer enhanced protection against oxidation and rust. The galvanization process not only improves the lifespan of the gasket but also maintains its mechanical integrity under varying temperature and pressure conditions. As a result, galvanized gaskets are particularly beneficial in environments that are prone to moisture and chemical exposure.

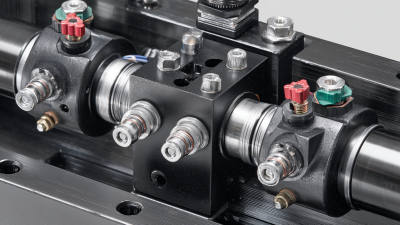

The properties of galvanized gaskets make them ideal for sealing applications in industries such as oil and gas, water treatment, and manufacturing. Their ability to withstand high pressures while preventing leaks is critical for maintaining operational efficiency. Additionally, the zinc coating provides a self-healing mechanism, allowing the gasket to repair minor abrasions, which is essential in prolonging its performance. Overall, understanding the composition and properties of galvanized gaskets highlights their significance in bolstering the reliability of industrial systems.

Galvanized gaskets have emerged as a favored choice in modern industrial applications due to their unique advantages. One of the primary benefits is their enhanced resistance to corrosion. The galvanization process involves coating the gasket material with zinc, which provides a protective layer that prevents rust and deterioration, especially in harsh environments where exposure to moisture and corrosive substances is common. This durability translates into longer service life and reduced maintenance costs, making galvanized gaskets an economically viable option for industries such as oil and gas, chemical processing, and marine applications.

In addition to corrosion resistance, galvanized gaskets offer superior sealing capabilities. Their ability to maintain a tight seal under varying temperatures and pressures minimizes the risk of leaks, which is critical for ensuring safety and operational efficiency. The reliability of these gaskets helps industries comply with strict environmental regulations, reducing the likelihood of hazardous spills. Furthermore, the ease of installation and compatibility with various flange materials make galvanized gaskets an attractive choice for engineers and maintenance professionals striving for optimal performance in their systems.

When evaluating gasket materials for modern industrial applications, a comparative analysis between galvanized gaskets and traditional gasket materials reveals significant advantages. Galvanized gaskets, made from steel coated with zinc, offer superior corrosion resistance, making them particularly valuable in environments with moisture and harsh chemicals. Traditional materials, such as cork or rubber, often struggle to maintain integrity under intense conditions, leading to leaks and increased maintenance costs.

Tips: For industries focusing on longevity and reduced downtime, consider switching to galvanized gaskets. Their enhanced durability translates to fewer replacements and longer operational lifespans, ultimately saving on costs associated with gasket failures.

Moreover, galvanized gaskets provide better mechanical properties such as higher tensile strength and resistance to deformation. In contrast, traditional gaskets may compress or deteriorate over time when exposed to heat and pressure, resulting in compromised sealing capabilities. Ensuring a reliable and leak-free operation is crucial, especially in sectors such as oil and gas, where failure can have severe repercussions.

Tips: When selecting a gasket for high-pressure applications, prioritize galvanized options to maximize safety and efficiency. Always consult material specifications to ensure compatibility with your system’s requirements.

Galvanized gaskets have become increasingly prevalent in various industrial applications due to their enhanced durability and resistance to corrosion. One primary area where these gaskets find extensive use is in the automotive industry. They are commonly employed in engines and exhaust systems, where the ability to withstand high temperatures and prevent leaks is critical. The galvanized coating on these gaskets adds an extra layer of protection, ensuring that components remain sealed and functional under demanding conditions.

Another significant application is in the oil and gas sector, where galvanized gaskets are used in pipelines and valves. The corrosive nature of crude oil and natural gas creates a challenging environment for traditional sealing materials. However, galvanized gaskets provide reliable performance, reducing the risk of leaks that could lead to environmental hazards and costly downtime. Additionally, industries such as manufacturing and power generation also benefit from these gaskets, as they contribute to the overall efficiency and safety of the equipment they seal. The versatility and effectiveness of galvanized gaskets continue to make them a preferred choice across multiple sectors.

| Industry | Application | Benefits | Temperature Resistance (°C) | Pressure Resistance (MPa) |

|---|---|---|---|---|

| Oil & Gas | Pipeline Sealing | Corrosion Resistance | -40 to 120 | 20 |

| Automotive | Engine Components | Leaking Prevention | -20 to 150 | 25 |

| Chemical Processing | Reaction Vessels | Chemical Resistance | -30 to 200 | 15 |

| Marine | Boat Hulls | Durability | -10 to 100 | 18 |

| Construction | Structural Seals | Long-Lasting Seals | -20 to 130 | 30 |

Galvanized gaskets have become integral components in modern industrial applications, particularly due to their outstanding maintenance and longevity. The process of galvanization, which involves coating gaskets with zinc, provides an added layer of protection against corrosion. This is especially crucial in industries that require rigorous safety standards and reliability, such as oil and gas, chemical processing, and water treatment. By preventing rust and deterioration, galvanized gaskets significantly reduce the frequency of maintenance interventions, thus lowering operational costs.

In addition to their corrosion resistance, galvanized gaskets are designed to withstand varying temperatures and pressures, making them ideal for demanding environments. Their durability extends the lifespan of both the gasket itself and the machinery utilizing it, ensuring optimal performance over time. Regular inspections and maintenance schedules highlight their low wear rates, enabling maintenance teams to focus on other critical machinery without the constant worry of gasket failure.

Ultimately, the strategic use of galvanized gaskets enhances equipment reliability and operational efficiency in industrial settings.