In the competitive landscape of manufacturing, selecting the right Progressive Die Parts is crucial for ensuring production efficiency and product quality. According to a report by Smithers Pira, the global market for die-making is expected to reach $8.0 billion by 2025, highlighting the importance of precise component selection in reducing operational costs and improving throughput. With progressive dies playing a pivotal role in high-volume stamping processes, it is essential for engineers and manufacturers to be well-informed about the factors that influence the performance and longevity of these parts. This blog will explore the five best tips for choosing Progressive Die Parts tailored for your specific projects, ensuring you maximize both your investment and output efficiency.

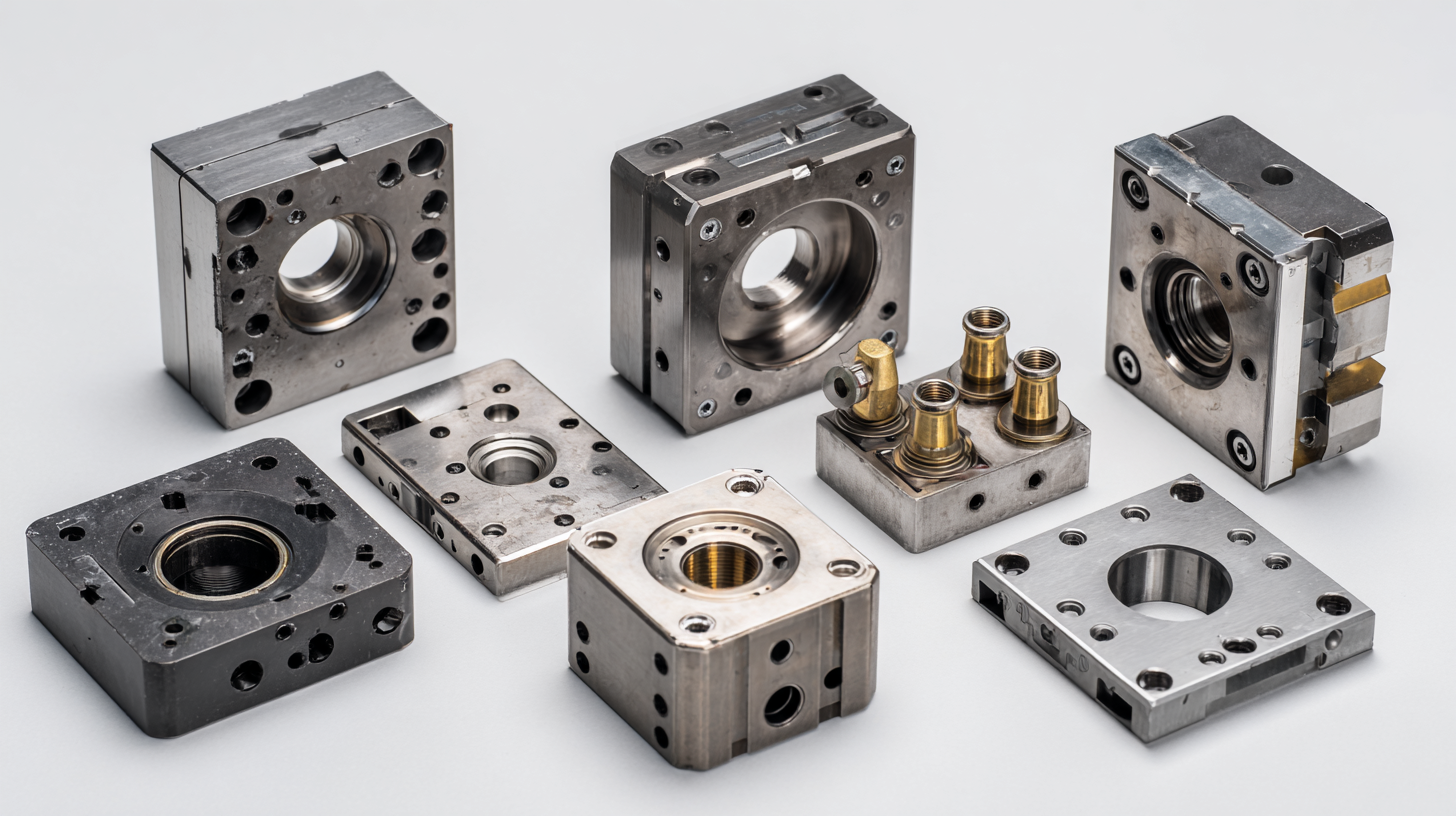

When it comes to manufacturing progressive die parts, material selection is a critical factor that can significantly influence the efficiency and longevity of your project. The materials used in producing these intricate components must not only meet the specific requirements of the application but also withstand the stresses of the forming processes. Choosing the right materials can enhance the performance, reduce maintenance costs, and improve the overall production cycle times. Common materials include high-carbon steel, tool steel, and certain alloys, each offering unique properties that cater to specific needs.

Understanding the material's mechanical properties, such as tensile strength, hardness, and ductility, will guide you in making informed choices. For instance, high-carbon steels are often preferred for their hardness and wear resistance, especially in applications involving heavy loads and high-impact scenarios. On the other hand, certain non-ferrous metals might be better suited for projects requiring corrosion resistance. Additionally, considering the compatibility of the chosen material with existing manufacturing processes is essential to ensure that the part can be efficiently produced without compromising quality.

When selecting progressive die parts for your projects, evaluating tolerance specifications is crucial for achieving optimal performance. Tolerances define the acceptable limits of variation in a part's dimensions, which directly influences the fit and functionality of the final assembly. Understanding the specific requirements of your project will help you choose parts that meet or exceed these tolerances, ensuring that they integrate seamlessly with other components. It's essential to assess how tight or loose these tolerances should be based on the intended application, as excessive tolerance can lead to issues like increased wear or misalignment over time.

In addition, collaborating with manufacturers who have a proven track record in producing high-quality progressive die components is beneficial. They can provide insights into the best tolerance specifications for your design. As you assess potential parts, consider the materials and the manufacturing processes involved; these factors can significantly impact the tolerances achievable in production. By placing a strong emphasis on appropriate tolerance evaluation, you can ensure that your progressive die parts not only meet your current project needs but also contribute to overall efficiency and effectiveness throughout their lifecycle.

When selecting progressive die parts for your projects, assessing die longevity is crucial. Various factors influence the durability of these components, with material selection being paramount. According to a report by the National Association of Manufacturers, parts made from high-quality steel can last up to 500,000 cycles, significantly reducing downtime and maintenance costs. Choosing the right steel alloy, such as D2 tool steel, offers optimal wear resistance and thermal stability, essential for high-volume production runs.

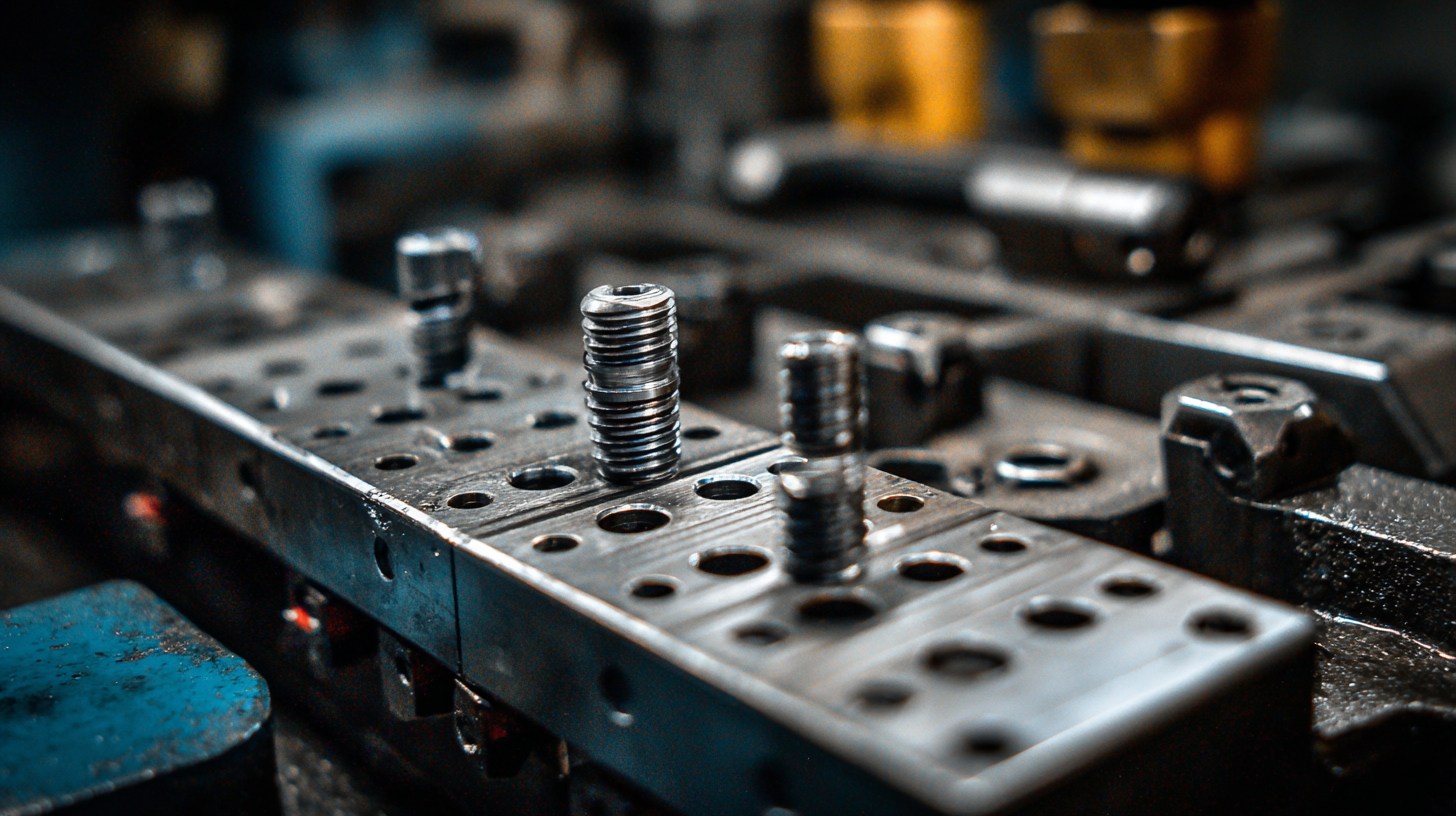

Another key factor is the precision of the die design and construction. The Fabricators & Manufacturers Association emphasizes that a well-engineered die can enhance its lifespan by 30% to 50%. Precision components ensure better alignment and reduce unnecessary stress on parts during operation. Additionally, maintaining proper lubrication and adopting advanced coating technologies can further extend the life of die parts, preventing premature wear and tear. Utilizing these strategies can significantly impact your project's overall efficiency and cost-effectiveness.

| Factor | Description | Impact on Longevity | Recommended Materials |

|---|---|---|---|

| Material Quality | The type and grade of material used in die parts. | High-quality materials improve wear resistance and overall longevity. | Tool Steel, Carbide |

| Design Precision | Accuracy in die design and manufacturing processes. | Precise designs reduce friction and misalignment wear. | CAD/CAM Software Enabled Designs |

| Heat Treatment | Processes to enhance hardness and durability of die parts. | Proper heat treatment vastly improves wear characteristics. | Quenching and Tempering Techniques |

| Maintenance Practices | Regular inspection and upkeep of die parts. | Consistent maintenance can prevent unexpected failures and prolong service life. | Lubricants, Cleaning Solutions |

| Operating Conditions | Environment in which die parts are used, including load and speed. | Extreme conditions can lead to rapid wear and failure. | Optimized Workload Specifications |

When selecting progressive die parts for your projects, it's crucial to analyze cost-effectiveness by balancing quality and budget. According to a recent industry report from the Precision Metalforming Association (PMA), over 60% of manufacturers cite cost as a primary factor in their procurement processes. However, it’s essential to recognize that opting for the cheapest components can lead to long-term expenses, often referred to as the "hidden costs" associated with poor-quality parts, which include increased maintenance and reduced machine efficiency.

Investing in high-quality die parts can significantly improve production speed and accuracy. A study conducted by Techspex revealed that manufacturers who prioritize quality see a 25% increase in throughput and a 30% reduction in scrap rates. This data highlights that spending slightly more upfront on superior materials can yield substantial savings over time, ultimately enhancing your bottom line. Therefore, when choosing parts, consider both the initial costs and the potential impact on your operational efficiency to strike the right balance between quality and budget.

In the world of progressive die design, integrating advanced technologies can significantly enhance efficiency throughout the production process. The incorporation of automation and computer-aided design (CAD) systems not only streamlines workflows but also allows for precise adjustments, reducing the likelihood of errors. These technologies facilitate the simulation of die performance under various conditions, enabling engineers to identify potential issues before physical prototypes are created. By leveraging such innovations, manufacturers can minimize trial-and-error phases, thus saving time and resources.

Another critical aspect of incorporating advanced technologies is the use of real-time data analytics. By monitoring the performance of die parts during operation, engineers can gather valuable insights that inform future design modifications. This data-driven approach enables continuous improvements, ensuring that the progressive dies not only perform optimally but also adapt to changing production demands. Embracing these technologies is crucial in achieving a competitive edge in today's fast-paced manufacturing environment, allowing companies to produce high-quality components with greater efficiency and adaptability.