When it comes to vehicle maintenance and performance enhancement, selecting the right components is crucial. One vital category of parts that often requires careful consideration is Stamping Auto Parts. These components, which are crafted through precision stamping processes, play a significant role in the overall functionality and durability of various automotive systems. As the automotive market evolves, understanding how to choose the best Stamping Auto Parts becomes increasingly important for vehicle owners and enthusiasts alike.

In this guide, we will explore key factors influencing the selection of Stamping Auto Parts for your vehicle. Whether you are looking to replace worn-out components or upgrade for better performance, the quality and compatibility of these parts can make a substantial difference. From materials and manufacturing techniques to compatibility with your vehicle model, making informed decisions can lead to enhanced safety, performance, and longevity. Join us as we delve into the essential considerations that will help you make the best choice for your vehicle's needs.

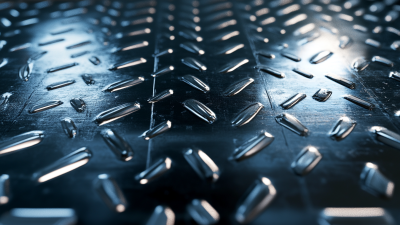

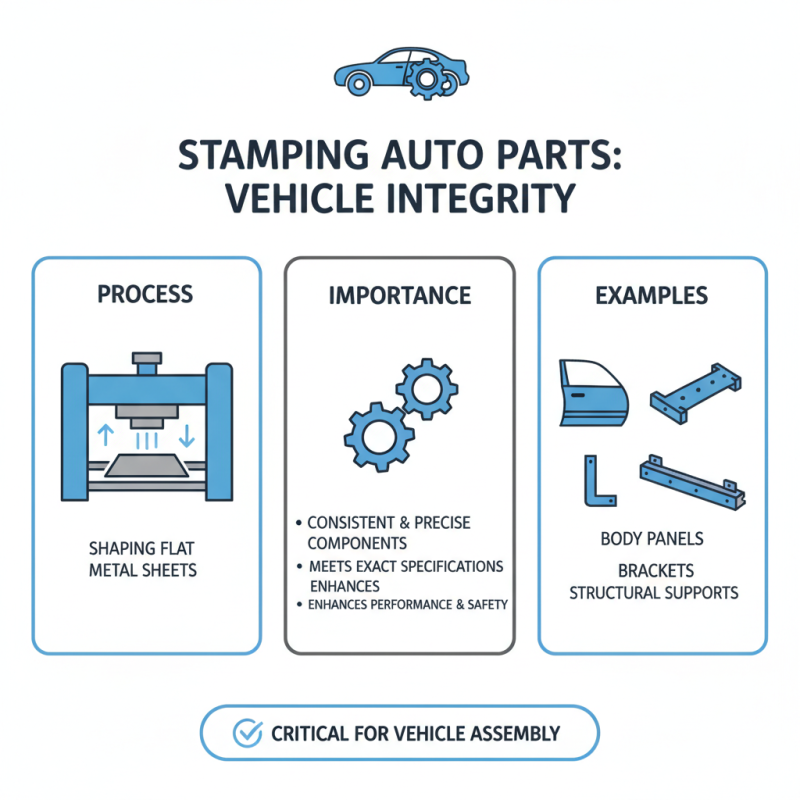

Stamping auto parts are essential components in the manufacturing and assembly of vehicles. These parts are created through a process that involves shaping flat metal sheets into specific forms using a stamping press. The importance of stamping auto parts lies in their ability to produce consistent and precise components that meet the exact specifications required for vehicle performance and safety. Common examples include body panels, brackets, and structural supports, all of which play a critical role in the overall integrity of a vehicle.

Understanding the significance of these parts extends beyond mere functionality; it also encompasses factors like weight, strength, and cost-effectiveness. Stamping allows for efficient mass production, which reduces manufacturing costs and enables the use of lighter materials that contribute to improved fuel efficiency. Furthermore, advances in stamping technology facilitate the creation of complex designs that enhance both aesthetics and aerodynamic performance. Thus, having a solid understanding of stamping auto parts is crucial for manufacturers and consumers alike, ensuring that vehicles not only meet regulatory standards but also perform optimally on the road.

When selecting stamping auto parts for your vehicle, there are several key factors to consider to ensure optimal performance and compatibility. One critical aspect is the material quality; high-grade metals like stainless steel and aluminum are preferred for their durability and resistance to corrosion. According to a report from the Auto Parts Manufacturing Association, approximately 65% of automotive failures are attributed to inferior parts quality, highlighting the importance of sourcing parts from reputable manufacturers.

Another essential factor is the compatibility of the parts with your vehicle’s specifications. Each vehicle model has unique requirements, and using parts that do not match these specifications can lead to performance issues. The Society of Automotive Engineers (SAE) states that mismatched parts can result in a 20%-30% increase in maintenance costs over time. Therefore, always check the manufacturer's part numbers and consult your vehicle's service manual to ensure the right fit.

Finally, consider the stamping technique used in manufacturing the parts. Advanced techniques, such as progressive die stamping or precision stamping, can produce parts that offer tighter tolerances and enhanced structural integrity. A study by the International Journal of Automotive Technology found that components produced with state-of-the-art stamping techniques showed a reduction in failure rates by up to 40%. Thus, opting for parts made with advanced stamping methods can significantly improve your vehicle's reliability and performance.

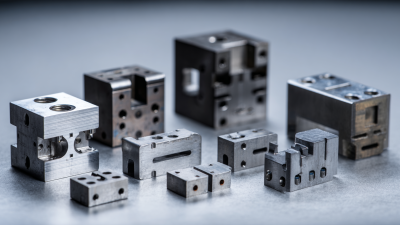

When selecting stamping auto parts for your vehicle, it's crucial to understand the different materials used in their production. Common materials include steel, aluminum, and advanced composites. Each material offers distinct advantages that cater to specific needs. For instance, steel is known for its strength and durability, making it an excellent choice for high-stress applications. On the other hand, aluminum is lighter and provides better corrosion resistance, which can enhance fuel efficiency. Advanced composites, although often more expensive, offer unique performance benefits, including weight savings and high resistance to environmental factors.

Tips: When choosing materials, consider the climate and driving conditions you typically encounter. For example, if you live in a coastal area, opt for materials with superior corrosion resistance like aluminum or treated steel.

It's also important to evaluate not just the material but the manufacturing process used to create the parts. Techniques like deep drawing or progressive stamping can affect the quality and precision of the final product. Investing in high-quality stamped parts can significantly impact your vehicle's performance and longevity.

Tips: Research suppliers' manufacturing capabilities and ask for samples when possible, as this will give you a better understanding of the material quality and craftsmanship before making a purchase.

When selecting stamping auto parts for your vehicle, evaluating the manufacturer's reputation is crucial. A well-established manufacturer typically offers products that have undergone rigorous testing and meet industry standards. Look for companies that have been in the business for several years and have a track record of reliability and quality. Customer reviews and testimonials can provide invaluable insights into a manufacturer’s reputation, highlighting both strengths and weaknesses in their products.

In addition to reputation, product quality should be a primary consideration. High-quality stamping auto parts are essential for ensuring the longevity and performance of your vehicle. Research the materials used in manufacturing, as premium materials often lead to better durability and resistance to wear and tear. Certifications from recognized industry organizations can serve as proof of a manufacturer's commitment to quality. By prioritizing these factors—manufacturer reputation and product quality—you can make an informed decision that enhances the overall performance and safety of your vehicle.

| Criteria | Description | Rating Scale (1-5) | Example Score |

|---|---|---|---|

| Manufacturer Reputation | Consider how long the manufacturer has been in business and their overall reputation in the industry. | 1 (Poor) - 5 (Excellent) | 4 |

| Quality Certifications | Check if the manufacturer has quality certifications like ISO or TS. | 1 (None) - 5 (All) | 5 |

| Material Quality | Evaluate the type of materials used in production. | 1 (Low) - 5 (High) | 4 |

| Warranty and Support | Assess the warranty and customer support offered. | 1 (Poor) - 5 (Excellent) | 5 |

| Customer Reviews | Look for feedback from previous customers about their experiences. | 1 (Negative) - 5 (Positive) | 4 |

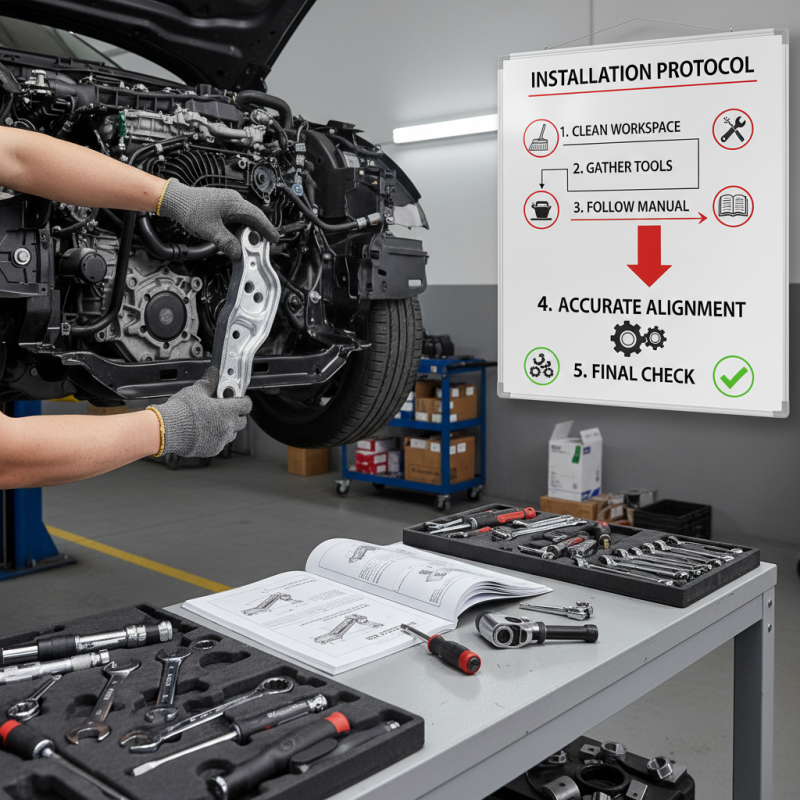

When it comes to installing stamping auto parts, proper technique is crucial to ensure optimal performance and longevity. First, always begin with a clean workspace and gather the necessary tools, such as wrenches, screwdrivers, and any specific tools required for the parts being installed. Follow the manufacturer's guidelines closely, as each part may have unique installation requirements. Taking the time to align parts accurately can prevent premature wear and tear on both the new components and your vehicle.

Maintenance is equally important after installation. Regularly inspect your stamping auto parts for signs of wear, corrosion, or other damage. Cleaning these parts with appropriate cleaners can prevent build-up that may lead to functional issues. Additionally, it's advisable to review the installation tension and torque specifications periodically to ensure the parts remain securely fitted. Keeping a maintenance schedule can also help catch potential problems early, ensuring your vehicle continues to perform efficiently.