When it comes to cutting various materials, choosing the right tools is crucial. One option that stands out is the Metal Cutting Diamond Disc. This disc offers durability and precision, making it ideal for both professional and DIY projects. With its diamond-encrusted surface, it provides superior cutting performance.

Many users report that using a Metal Cutting Diamond Disc reduces wear and tear on tools. It can slice through tough metals effortlessly, saving time and effort. However, some may find it challenging to choose the right disc for their specific needs. Not all diamond discs are the same, and that can lead to confusion.

Moreover, while these discs are powerful, they also require careful handling and maintenance. Users must consider safety precautions to prevent accidents. The initial cost might be higher, but the long-term benefits often outweigh this investment. With proper research and consideration, the Metal Cutting Diamond Disc could be an excellent addition to your toolkit.

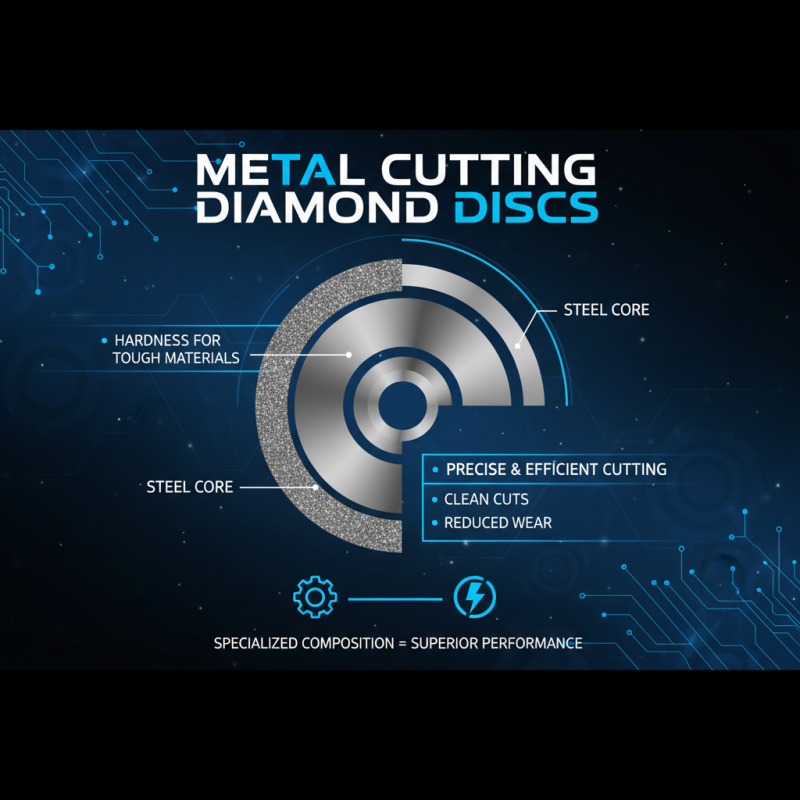

Metal cutting diamond discs are specialized tools designed for precise and efficient cutting. These discs have a unique composition that makes them ideal for cutting metals. They are typically made with a steel core and a diamond grit surface. The diamonds provide the hardness needed to cut through tough materials. This composition is crucial for achieving clean cuts and reducing wear on the discs.

The diamond grit on these discs comes in various sizes. Finer grit offers smoother cuts, while coarser grit works faster but may leave rough edges. It's essential to choose the right grit depending on the cutting needs. Not all metal cutting tasks are equal; some require speed, while others need precision. Understanding these differences can influence the choice of the right disc.

Moreover, using metal cutting diamond discs comes with its share of challenges. They can become dull over time, and monitoring their condition is essential. Users might overlook signs of wear, leading to less effective cutting. Regular inspection ensures optimal performance and longevity of the disc. This awareness can save time and resources in the long run.

Metal cutting diamond discs have become essential tools in various industrial applications. Their durability is unmatched, especially when cutting hard materials. These discs are designed to last much longer than traditional blades, which means fewer replacements. This can lead to significant cost savings over time. Their efficiency is evident; they cut through metals with speed and precision.

Another advantage is their ability to produce cleaner cuts. Metal cutting diamond discs reduce the risk of chipping or rough edges. This is crucial for industries that prioritize quality in their finished products. Workers often report less stress during operations, as these discs enhance control and stability. However, the initial investment can be a hurdle for some. The cost may deter smaller businesses from upgrading.

Moreover, proper maintenance is vital. Without regular care, even the best discs can underperform. Users must be informed about the best ways to handle and store their cutting tools. Awareness of these factors can lead to better decision-making. Metal cutting diamond discs have clear advantages, but understanding their limitations is equally important.

| Feature | Description | Benefits |

|---|---|---|

| Durability | Can withstand high temperatures and pressures during cutting. | Longer tool life, reducing replacement frequency and costs. |

| Cutting Precision | Offers precise wall thickness and smooth finishes. | Minimizes rework and scrap materials, saving time and resources. |

| Versatility | Effective for cutting various materials including metal and masonry. | Ideal for multiple applications, reducing the need for different tools. |

| Reduced Vibration | Minimizes vibrations during operation. | Provides better control and enhances user comfort during cutting tasks. |

| Cost-Effectiveness | Higher initial investment but lower long-term costs due to durability. | Over time, they prove more economical than traditional cutting solutions. |

When considering metal cutting diamond discs, it's crucial to understand their performance metrics. The quality of a diamond disc can significantly impact your cutting efficiency. High-performance discs will yield cleaner cuts and last longer. Factors like diamond concentration and bond type are significant. A well-balanced disc can cut through tough materials efficiently.

Tip: Always check the specs. This will help you choose the right disc for your material. Not all discs are suitable for every type of metal. It's easy to grab the first one you see, but it might not be the best choice.

Moreover, the right cutting speed is vital. Each disc has an optimal RPM range. Using a disc outside this range can lead to poor performance or faster wear. Efficiency may drop if the wrong speed is used. This is often overlooked.

Tip: Test on scrap material first. This will give you a feel for how the disc performs. Adjust your technique based on the results. Remember, even small adjustments can lead to significant improvements in results.

Metal cutting diamond discs have gained popularity for their efficiency and durability. When looking at diamond discs versus traditional abrasive tools, the differences become clear. Diamond discs provide cleaner cuts and last longer than standard abrasives. They cut through hard materials with ease, reducing time spent on each project. While traditional tools may wear down quickly, diamond discs maintain their sharpness longer.

However, not everything is perfect. Diamond discs can be more expensive initially, which may deter some users. Additionally, they require careful handling to avoid damage. Abrasive tools, while less efficient, can be more accessible for beginners. Sometimes, the learning curve with diamond discs can be steep. If a user isn’t familiar with the right techniques, mistakes can happen. These errors can lead to wasted materials and time.

Overall, the choice between diamond discs and traditional tools depends on the user's needs. Each option has its pros and cons. For professionals requiring precision, diamond discs often prove superior. Yet, for casual users, traditional tools might be easier to use and more practical. Evaluating your specific cutting tasks will guide you toward the right decision.

When considering cutting solutions, metal cutting diamond discs stand out for their efficiency. According to industry reports, diamond discs can outlast traditional blades by up to 20 times. This durability translates to fewer replacements and less downtime, making them a cost-effective choice over time.

In terms of long-term savings, a study by the American Masonry Institute highlights that professionals can save approximately 30% on overall cutting costs. This figure includes direct savings from reduced tool replacements and indirect benefits like faster project turnaround times. Diamond discs maintain their sharpness longer, which also reduces energy consumption during operations. The upfront investment might appear higher, but the return on investment often pays off swiftly.

Moreover, some users may find the initial learning curve challenging when switching to diamond cutting solutions. Training staff and adapting processes take effort. However, the performance benefits usually far outweigh these hurdles. With increased productivity and lower material waste, the long-term advantages are clear. Investing in diamond discs is not just a purchase; it's a strategic decision towards better productivity and profitability.