Choosing the right angle grinder disc for metal cutting is a critical decision that can significantly impact the efficiency and quality of your work. According to industry expert John Smith, a seasoned professional in metal fabrication, "Using the correct angle grinder disc metal not only enhances performance but also ensures safety during the cutting process." His insight underscores the importance of matching the disc to the specific type of metal being worked on, as well as the intended application.

Understanding the variables involved in selecting an angle grinder disc metal can make a world of difference for professionals and DIY enthusiasts alike. Factors such as the material composition of the disc, grit size, and disc diameter all play pivotal roles in achieving optimal results. With a myriad of options available in the market, it becomes crucial to make informed choices that align with the project's requirements, ultimately leading to superior craftsmanship and a safer working environment.

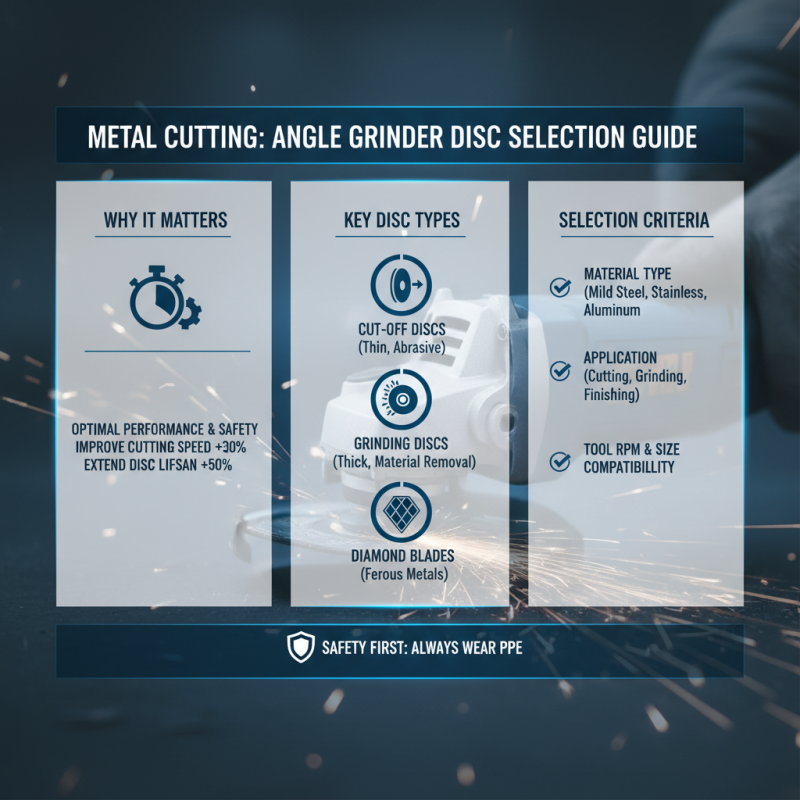

When it comes to metal cutting, selecting the right angle grinder disc is crucial for achieving optimal performance and safety. Understanding the different types of angle grinder discs available can significantly impact the efficiency of your projects. According to industry reports, the right choice can improve cutting speed by up to 30% and extend the lifespan of the disc by approximately 50%. This is particularly relevant in industrial settings where precision and productivity are paramount.

There are various types of angle grinder discs designed specifically for metal cutting, including abrasive discs, diamond blades, and specialized cutting wheels. Abrasive discs are generally favored for their versatility and cost-effectiveness, ideal for lighter tasks. In contrast, diamond blades are engineered for heavier applications and can cut through harder metals, providing a cleaner finish and longer durability. Specialized cutting wheels, often designed with unique geometries, enhance material removal rates, allowing for greater efficiency and reduced operational costs in high-volume environments.

Understanding the specific characteristics and intended applications of these discs is essential for anyone involved in metal fabrication or construction. The right disc not only improves work quality but also contributes to safer operating practices by minimizing risks associated with improper tool use. As the market continues to evolve, professionals are encouraged to stay informed about new developments and technologies, ensuring they leverage the best tools available for their specific tasks.

When selecting an angle grinder disc for metal cutting, several key factors must be considered to ensure optimal performance and safety. One of the most crucial elements is the disc material. For instance, aluminum oxide is commonly used for general-purpose grinding, while zirconia alumina discs can withstand higher temperatures and offer extended durability, making them ideal for heavy-duty applications. According to a report by the American National Standards Institute (ANSI), using the appropriate material can improve cutting efficiency by up to 30%, significantly reducing the amount of time spent on tasks and minimizing wear on the grinder itself.

Another critical factor is the disc size and thickness. A thicker disc provides greater stability and is less likely to break under pressure, which is essential for cutting thicker metals. The Occupational Safety and Health Administration (OSHA) emphasizes the importance of matching the disc size to the grinder’s RPMs to avoid dangerous situations that can lead to disc failures. For example, a typical 5-inch grinder might use discs rated for 12,000 RPM, highlighting the necessity of adhering to manufacturer specifications for a safe and effective cutting operation.

Additionally, the type of cut required influences the choice of grinder disc. For precision cuts, a thinner disc may be preferable, providing finer and cleaner edges. In contrast, a thicker disc is more suitable for heavy removal of material. Researchers indicate that incorrect disc selection can lead to increased fatigue, inefficiency, and even injuries on the job site. Therefore, understanding these key factors not only enhances performance but also ensures the safety and longevity of both the tool and the professional utilizing it.

When it comes to metal cutting with an angle grinder, the choice of disc size and thickness plays a crucial role in determining cutting performance. A larger disc diameter can enhance the cutting speed and efficiency, allowing for faster removal of material. This is particularly vital in applications requiring extensive cuts or working with thick metal. However, using a larger disc also means that it may be harder to control, so operators must be skilled in maneuvering this increased power safely and effectively.

Thickness is another key factor impacting performance. Thinner discs are typically more suitable for precision cutting and allow for cleaner, finer cuts, which is ideal for intricate work. Conversely, thicker discs are more durable and provide greater control during heavy-duty applications but may produce more heat and a larger kerf, potentially distorting the metal being cut. Selecting the right combination of disc size and thickness thus ensures optimal performance tailored to specific tasks, enhancing both safety and efficiency in metalworking endeavors.

When selecting the right angle grinder disc for metal cutting, the choice of

material plays a critical role in the effectiveness and safety of the task. The most commonly used materials for

cutting discs include aluminum oxide, zirconia alumina, and ceramic. Each material has

unique properties suited to different types of metal. According to industry reports, aluminum oxide discs provide an

excellent balance of performance and cost-effectiveness, making them ideal for general metal cutting tasks. In contrast,

zirconia alumina discs are preferred for tougher metals due to their

durability and longer lifespan, which can enhance productivity by reducing the frequency of disc changes.

Tips for choosing the right material include evaluating the type of metal you'll be working with. For

mild steel, aluminum oxide is typically sufficient; however, for

stainless steel or high-density alloys, consider using zirconia alumina discs. You

should also assess the cutting speed and the thickness of the metal. Thinner metal may benefit from a finer grain disc,

providing a smoother cut, while thicker materials may require a more aggressive disc to ensure efficient cutting.

According to a 2021 report from the International Abrasives Association, selecting

the appropriate disc can improve cutting efficiency by up to 30%, minimizing both time and

material waste in metalworking operations.

Understanding the bonding agent is another vital aspect. Most cutting discs utilize resin bonds, but for

high-performance applications, metal-bonded discs offer superior longevity. A

recent market analysis highlighted that choosing the right bonding material could extend disc life by as much as

50%, significantly reducing operational costs. Thus, evaluating the metal type, cutting

speed, and bonding material will ensure you select the optimal cutting disc for your project.

When using an angle grinder for metal cutting, safety precautions are paramount to prevent accidents and injuries. Always wear appropriate personal protective equipment (PPE) including safety glasses, gloves, and a face shield to protect yourself from flying debris and sparks. Ensure that your workspace is clear and free of flammable materials. Additionally, be mindful of your surroundings and ensure there are no bystanders in close proximity.

To maximize safety while using an angle grinder, consider these key tips. First, check the grinder and disc for any signs of damage before use. A damaged disc can shatter during operation, leading to serious injuries. Second, maintain a firm grip on the grinder with both hands and use it at a steady angle to control the cutting process effectively. Lastly, familiarize yourself with the tool's manual and operating instructions; understanding the specific features and limitations of your grinder can significantly enhance safety while working.

Regular maintenance of your angle grinder is also essential. Ensure that the motor and guard are functioning properly, and that the disc is securely attached. Taking breaks during extended use helps prevent overheating and allows you to maintain focus. By following these precautions and tips, you can create a safer work environment while achieving efficient cutting results.