Choosing the right Angle Grinder Disc Metal is crucial for effective metal cutting. Expert Robert J. Parker emphasizes, "The disc can make or break your project." This statement underlines the importance of selecting the correct disc for your tasks.

Many factors affect your choice. The type of metal you are cutting matters greatly. Different metals require different disc materials and designs. A wrong choice can lead to poor results. It can also pose safety risks.

Consider the diameter and thickness of the disc as well. Each specification influences performance. It’s a common mistake to overlook these details. This oversight can result in wasted effort and resources. Make sure to research thoroughly before making a choice. Selecting the right disc is not just about the task; it affects your overall experience.

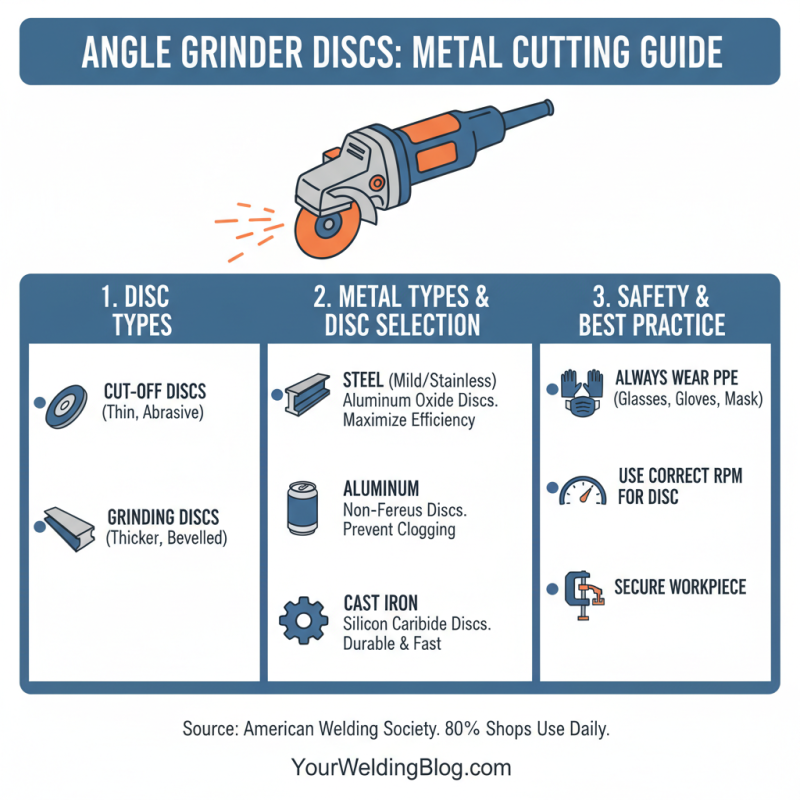

Choosing the right angle grinder disc for metal cutting is crucial for achieving precise results. Understanding different metal types is key to making an informed decision. According to the American Welding Society, over 80% of metal fabrication shops utilize angle grinders daily. Each metal type requires a specific disc to maximize efficiency and safety.

When working with softer metals like aluminum, opt for discs made from aluminum oxide. These discs cut smoothly and prevent clogging. In comparison, harder metals, such as stainless steel, benefit from zirconia or ceramic discs. These materials resist wear and provide longevity. A report from the Metal Industries Association highlighted that improper disc selection can lead to reduced productivity and increased costs, ultimately affecting project timelines.

Additionally, consider the metal's thickness and application. For thin materials, use a thinner disc for cleaner cuts. However, with thicker metals, a heavy-duty disc is essential for durability. Engineers assert that using the wrong disc can cause overheating or disc breakage. The wrong choice also impacts the finished product's quality, leading to potential rework. Know your metal types, and always reflect on your disc selection.

Choosing the right angle grinder disc for metal cutting involves understanding key specifications. The disc material is crucial. Stainless steel and aluminum discs are common, but they have limits. Make sure to match the disc to the metal type.

Another important factor is the diameter of the disc. Most angle grinders support various sizes, but not all discs fit all grinders. Check your grinder’s specifications before making a purchase. The thickness of the disc also affects performance. Thin discs cut faster, but they wear out quickly.

Tips: Always wear protective gear when using angle grinders. Checking the grit size can help. Finer grit means a smoother finish, but it may take longer. If you're cutting thicker metal, consider a thicker disc for durability.

Pay attention to the RPM rating on the disc. It should match your grinder's speed. A mismatch can lead to accidents. Lastly, avoid disc options that look damaged. They may break during use, posing safety hazards. Choose wisely and watch for any defects.

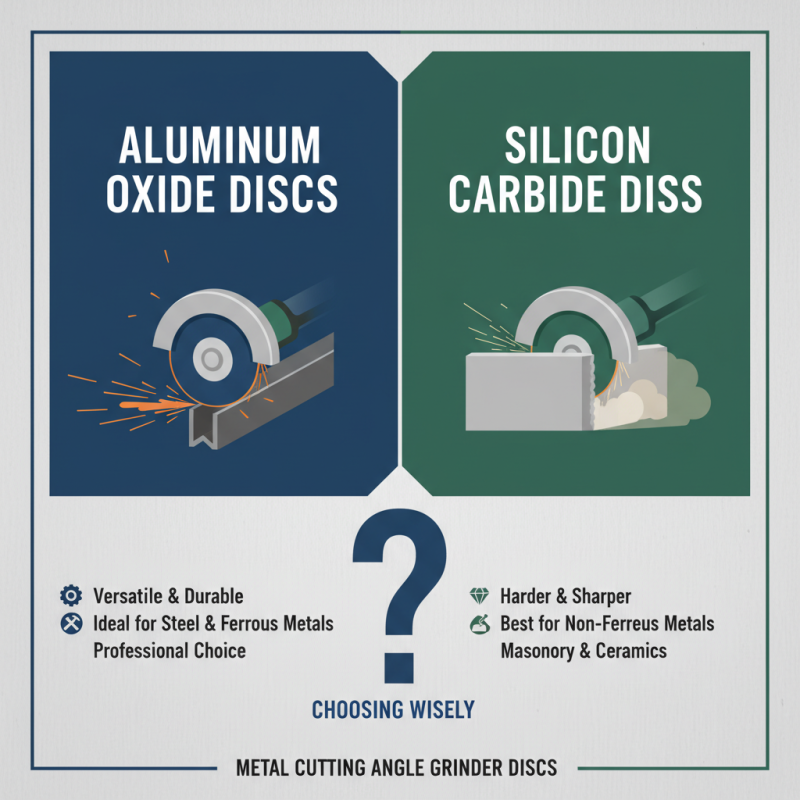

When it comes to metal cutting, choosing the right angle grinder disc is crucial. Two common types are aluminum oxide and silicon carbide. Each material has its own strengths and weaknesses. Aluminum oxide discs are popular for their versatility and durability. They perform well on steel and ferrous metals, making them a favorite among professionals.

Silicon carbide, on the other hand, excels in cutting hard materials like granite and porcelain. A recent industry report indicates that silicon carbide can achieve a higher cutting speed. However, it wears down faster when used on softer metals. This discrepancy can lead to inefficiencies in tasks. Many users overlook this critical aspect, leading to frequent disc replacements.

It's important to note that not all applications require the same disc. A choice based solely on material may not yield the best results. Proper evaluation of the type of metal and cutting conditions is essential. The wrong disc can result in poor cuts or excess heat generation. Ultimately, understanding these differences can lead to better choices and improved outcomes in metal cutting tasks.

When cutting metal, disc thickness plays a crucial role in the efficiency of your angle grinder. Thinner discs, usually around 1 to 2 mm thick, offer precision. They generate less heat and reduce material waste. This is particularly important for delicate cuts. On the other hand, thicker discs can handle tougher materials and larger jobs. They provide durability but can create more heat and deformation.

Choosing the right thickness also requires consideration of your skill level. If you're a beginner, thicker discs might seem easier to control. However, they can be less forgiving. You might end up with rough edges and excess material. Conversely, if you're experienced, a thinner disc can yield cleaner cuts. It demands more focus and skill, but the results can be impressive.

It’s easy to overlook disc thickness when selecting your tools. Sometimes, the wrong choice leads to frustration. Users often find themselves struggling with heat buildup or poor cutting efficiency. Experimenting with different sizes can help you understand their effects better. Remember, the right disc is out there. Finding it may take some trial and error.

| Disc Thickness (mm) | Cutting Efficiency | Best For | Pros | Cons |

|---|---|---|---|---|

| 1.0 | High | Thin metals, sheet metal | Fast cutting, clean edges | Less durable, wear quickly |

| 2.0 | Medium | General metal cutting | Balanced performance | Slower than thinner discs |

| 3.0 | Low | Thicker metals, heavy fabrication | Highly durable, longer lifespan | Slower cutting speed |

| 4.0 | Very Low | Thick steel, structural metal | Extended life for heavy jobs | Not ideal for precision work |

When using an angle grinder disc for metal cutting, safety is paramount.

Always wear proper personal protective equipment. This includes gloves, goggles, and ear protection. Be mindful of your surroundings. Ensure that the workspace is clear of flammable materials and that you have a stable footing. Check the condition of the disc before use. Look for any cracks or clear signs of wear. A damaged disc can lead to serious injuries.

Adhering to safety standards is crucial. Use the appropriate disc for the metal type you are cutting. Each disc has specific purposes. Using the wrong disc can lead to overheating and accidents. Maintain a firm grip on the grinder. Any slip can cause the grinder to kick back, resulting in injury. If you feel unsure, take a step back. Reflect on your actions and processes. It’s better to pause and rethink than to rush and risk harm.

Always respect the power of the tool.