Choosing the right Angle Grinder Disc Metal is crucial for any metalworking project. With various options available, selecting the appropriate disc for your task can be overwhelming. The global angle grinder market is projected to reach $5 billion by 2026, highlighting the importance of this equipment in the industry.

Expert in metalworking tools, John Smith, emphasizes, "The right disc can significantly enhance both efficiency and safety." This statement resonates within the industry, where performance hinges on proper selection. An unsuitable disc may lead to inadequate results and even safety hazards.

Many professionals overlook the impact of a specific disc type. For instance, using a cutting disc for grinding tasks can result in poor outcomes. Project efficiency can dwindle if tools are mismatched, illustrating the need for careful consideration. Ultimately, the right Angle Grinder Disc Metal can transform your project results.

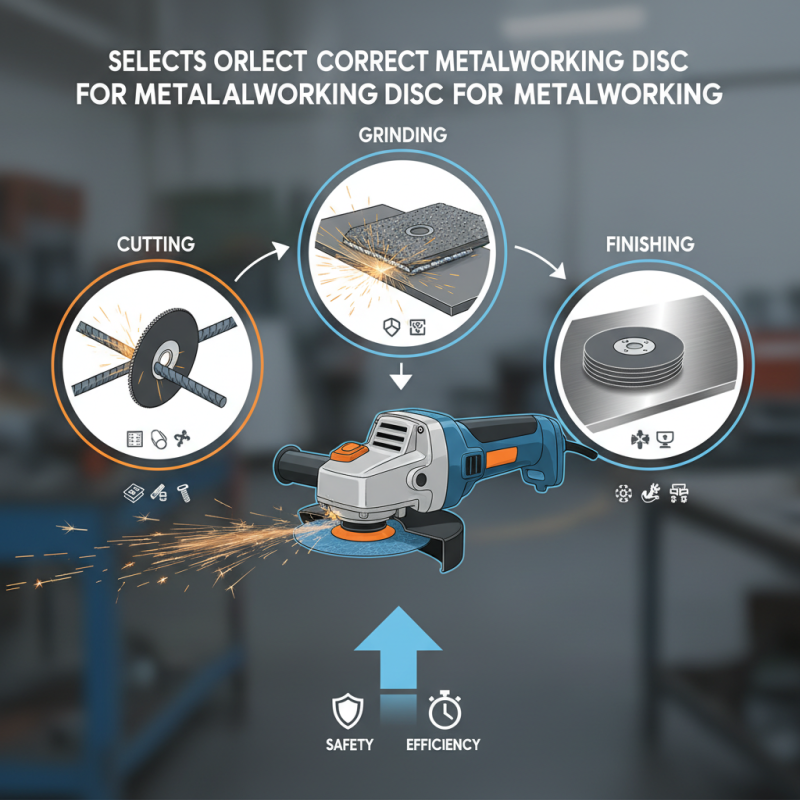

Choosing the right angle grinder disc for metalwork is essential for achieving the desired result. There are different types of discs, each suited for specific tasks. Cutting discs, for instance, are thin and designed for precise cuts in metal. They work well for sheet metal and pipes. Grinding discs are thicker and ideal for smoothing out surfaces. These discs help remove excess material, making them perfect for achieving a clean finish.

Flap discs combine grinding and polishing, making them versatile. They're especially useful for blending welds and finishing metal surfaces. However, using them incorrectly can lead to an uneven surface. It's crucial to choose the right grit. A finer grit offers a smoother finish, while a coarser grit removes more material.

When selecting a disc, consider the material you’re working with. Different metals require different approaches. Aluminum, for instance, needs a specific type of disc to avoid clogging. Mistakes in choosing the wrong disc can lead to unsatisfactory results and wasted materials. Understanding these details can enhance your metalwork projects significantly.

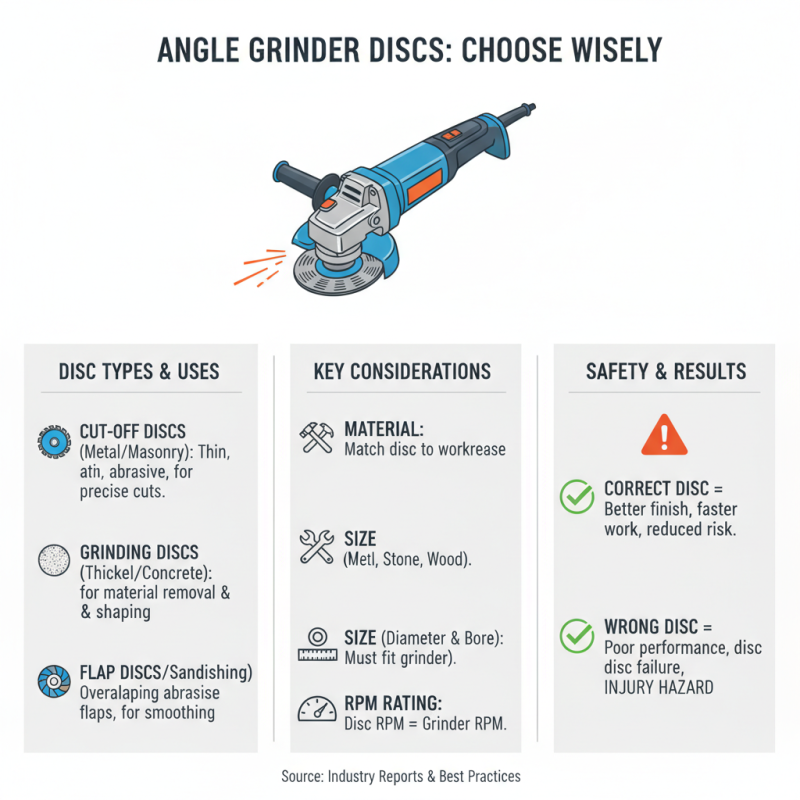

Choosing the right angle grinder disc is crucial for your projects. Various factors affect the selection. Understanding these can improve your results.

Material type is a primary consideration. Different metals require specific discs. For instance, aluminum can be tricky. It tends to clog standard discs, affecting performance. Research shows that 35% of workers face issues due to inappropriate materials.

Another factor is the grit level. A higher grit number means a finer finish. For refinishing tasks, between 120 and 320 grits work best. However, for quick cuts, coarser grits (24-60) are ideal. A fine balance is key. Some users find switching too frequent causes inconvenience.

Tips: Always match the disc to the grinder’s RPM. Mismatched speeds can be dangerous. Always prioritize safety gear when working with grinders. This cannot be overstated. Disregarding safety leads to risks.

Ultimately, testing different discs on scrap material can be wise. This allows you to gauge performance without putting your main project at risk. Stay curious and adapt based on your experiences. This approach leads to better results and understanding over time.

Choosing the right angle grinder disc is crucial for project success. Each disc type serves a specific purpose. Understanding disc specifications helps match them to your needs. For instance, metal cutting requires sharp, durable discs. According to industry reports, using the wrong disc can lead to poor results and safety hazards.

Disc thickness impacts performance. Thinner discs cut faster but wear out quickly. A thicker disc is more versatile. It lasts longer but can be slower. Research indicates that 40% of users choose the wrong thickness. This mistake can result in inefficient work and increased costs. Evaluating your project requirements can prevent these issues.

Material compatibility is another key factor. Different metals demand different discs. For example, stainless steel needs specialized abrasive materials. Reports show that 30% of users overlook this aspect. Not considering compatibility can lead to overheating and disc failure. Investing time in understanding your project’s demands is essential for effective results.

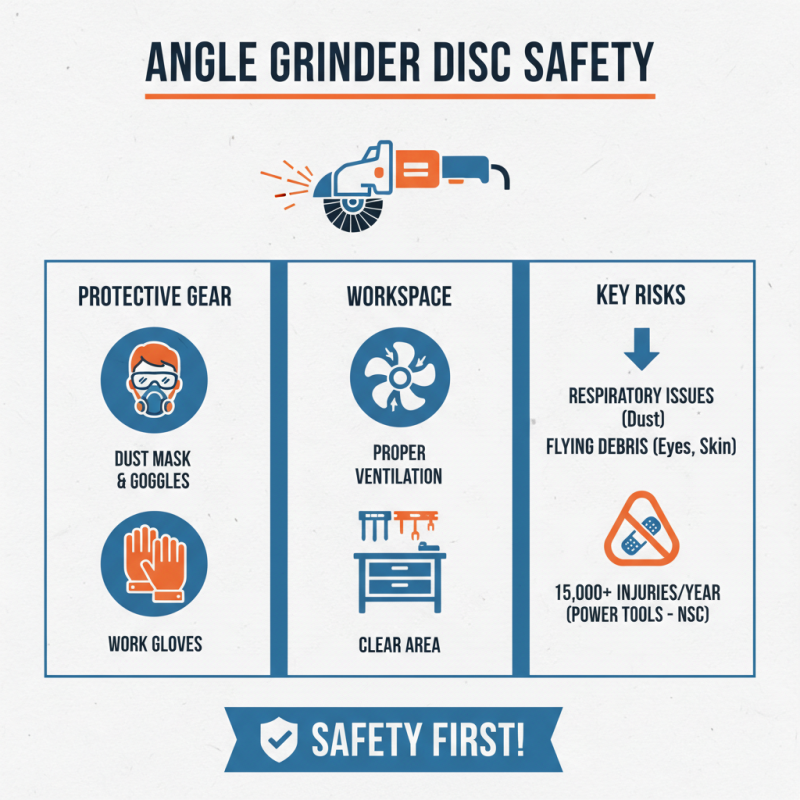

When using angle grinder discs, safety should always come first. Dust particles can cause respiratory issues. Ensure proper ventilation in your workspace. A report from the National Safety Council states that improper use of power tools leads to over 15,000 injuries annually. It’s essential to wear a dust mask and goggles to protect against flying debris.

Always inspect the discs before use. Look for signs of wear or damage. A cracked disc can shatter during operation, posing serious risks. According to industry experts, around 30% of injuries are due to equipment failure. This can often be avoided with diligent checks. Do not rush your work; haste can lead to accidents. Remember, a safe work environment leads to better productivity.

Proper grip and stance are crucial. Hold the grinder firmly with both hands. Stand to the side, not directly behind the tool. This reduces the chance of injury from kickback. Stay mindful of your surroundings. Other workers or loose materials can become hazards. It's vital to create a safe zone while grinding. Injuries from flying particles can happen anytime if precautions are not in place.

Maintaining angle grinder discs is crucial for optimal performance. Regular maintenance can extend the life of these tools, ensuring they work effectively for varying projects. A study shows that properly maintained tools can last up to 30% longer. Simple practices can make a significant difference.

One effective tip is to regularly clean the discs. Dust and debris can wear on the materials, reducing their lifespan. Use a soft brush or a cloth to remove any buildup. Additionally, inspect discs for signs of wear before each use. Cracks or uneven surfaces can lead to dangerous conditions. These small measures greatly improve safety and efficiency.

It's important to store discs in a dry place. Humidity can cause rust, which compromises the metal’s integrity. Discs should be kept flat to prevent bending or warping. Also, consider the type of material being cut or ground. For instance, using the wrong disc can lead to faster wear. These choices reflect a user’s understanding of their tools. Keeping careful notes on performance can reveal patterns and highlight areas for improvement.

| Disc Type | Material | Ideal Usage | Lifespan (Hours) | Maintenance Tips |

|---|---|---|---|---|

| Cutting Disc | Aluminum Oxide | Metal Cutting | 20-30 | Keep discs dry, store horizontally |

| Grinding Disc | Silicon Carbide | Surface Preparation | 15-25 | Use at recommended RPM, avoid excessive pressure |

| Flap Disc | Zirconia | Smoothing and Finishing | 30-40 | Regularly check for wear, rotate the disc |

| Resin Bonded Disc | Brown Fused Alumina | Versatile Grinding | 20-35 | Store in a moisture-free environment |

| Diamond Disc | Diamond Grit | Hard Materials Cutting | 40-80 | Use with cooling fluid, check for cracks |