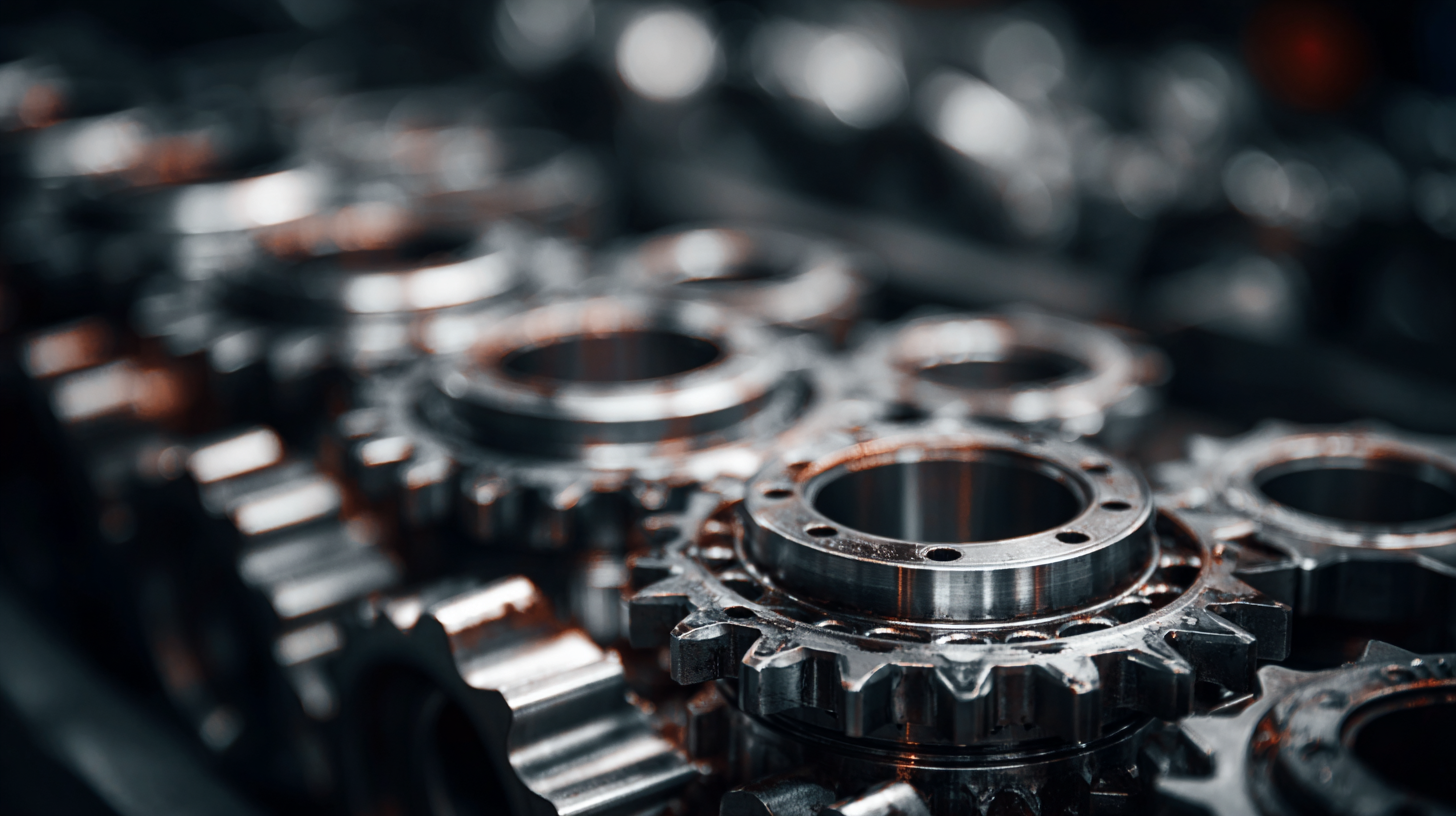

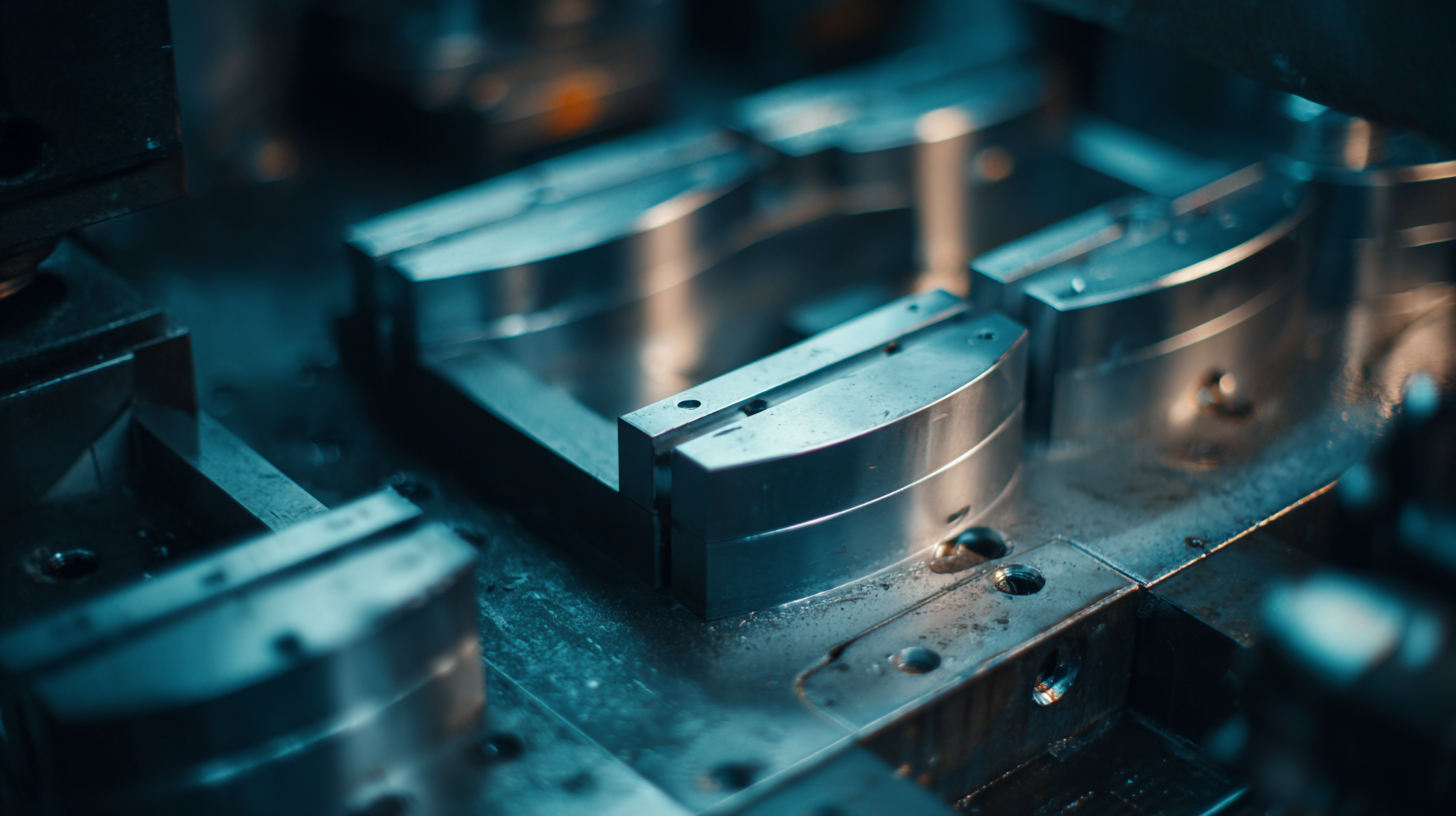

When embarking on an automotive project, selecting the right components is crucial for ensuring performance and reliability. Among these components, Automotive Metal Stamping Parts play a vital role in manufacturing precision and durability in vehicles. These parts are produced through a process that shapes metal sheets into predetermined forms, making them essential for various applications in the automotive industry, from body panels to structural supports.

Choosing the right Automotive Metal Stamping Parts involves considering factors such as material type, manufacturing tolerances, and design specifications. Understanding these elements not only aids in achieving the desired quality and longevity of the automotive components but also impacts the overall efficiency of the manufacturing process. This guide aims to provide insights and practical tips to help you navigate the selection process and make informed decisions that align with your project's specific needs.

When embarking on a project that requires automotive metal stamping parts, the quality of these components is paramount. High-quality parts not only ensure the durability and longevity of the final product but also significantly impact the overall safety and performance of vehicles. Investing in superior metal stamping components fosters reliability, which is especially crucial in the automotive industry, where even the smallest defect can lead to catastrophic failures.

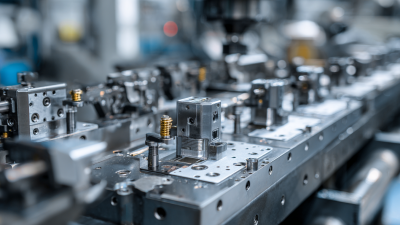

Moreover, understanding the manufacturing processes involved in producing automotive metal stamping parts can help you assess their quality. Factors such as the material used, precision in engineering, and adherence to industry standards all play vital roles in determining the integrity of the parts. Collaborating with reputable suppliers who prioritize quality control can mitigate the risks associated with inferior components, thus contributing to the success of your project while enhancing customer trust and satisfaction.

Identifying the specific needs and requirements of your project is crucial when choosing the right automotive metal stamping parts. Begin by assessing the functional requirements of your parts, including their use, load-bearing capabilities, and environmental conditions they'll face. Consider factors such as weight, strength, and corrosion resistance, which can significantly impact performance and longevity. Understanding these parameters will guide you toward materials and designs that align with your project goals.

Next, evaluate the production volume and timeline. Different stamping processes cater to varying scales of production, from prototypes to large-scale manufacturing. If you require a rapid turnaround for a small batch, techniques like CNC machining might be more suitable than traditional stamping methods. Additionally, ensure you account for quality standards and regulatory compliance pertinent to the automotive industry. By clearly defining these aspects, you can effectively narrow your options and select the most suitable stamping parts to meet your project's demands.

When evaluating material options for automotive metal stamping, it is essential to consider the specific requirements of your project. Different materials offer unique properties that can greatly impact the performance, durability, and cost-effectiveness of the stamped components. Common materials used in automotive metal stamping include steel, aluminum, and advanced high-strength steel (AHSS). Each of these materials has its advantages: while steel is renowned for its strength and formability, aluminum provides lightweight characteristics that enhance fuel efficiency.

In addition to material properties, the manufacturing process itself also plays a critical role in material selection. Factors such as stampability, weldability, and corrosion resistance are important for ensuring the final product meets industry standards and performs reliably over time. For instance, if your project demands intricate designs or tight tolerances, aluminum might be preferable due to its superior malleability. Conversely, if maximum strength is paramount, high-strength steel could be the better choice. Ultimately, understanding the application of the component will guide you towards the most suitable material for your automotive metal stamping project.

When selecting automotive metal stamping parts for your project,

it's essential to analyze the capabilities and experience of potential suppliers. A supplier’s industry experience can significantly impact the quality, durability, and overall performance of the parts you intend to use. Suppliers with a long-standing presence in the automotive sector typically possess a wealth of knowledge about material specifications, manufacturing processes, and industry standards. This expertise can help ensure that the parts meet your project's specific requirements.

Tip 1: Always look for suppliers who can provide references or case studies from previous projects in the automotive field. This practice can give you insights into their reliability and the performance of their parts.

In addition to experience, evaluating the supplier's technological capabilities is crucial. Advanced manufacturing techniques and equipment are indicators of a supplier's commitment to quality and innovation. A well-equipped supplier is more likely to produce precise and repeatable parts, reducing the risk of defects in your final product.

Tip 2: Request detailed information about the supplier’s manufacturing processes and quality control measures. Understanding their approach can help you gauge how they manage production challenges and ensure compliance with industry standards.

When selecting automotive metal stamping parts for your project, the balance between cost efficiency and quality is paramount. A report by Grand View Research highlights that the global automotive stamping market is projected to reach USD 32.21 billion by 2025, indicating a growing demand for durable and effective parts. However, while lower costs may seem appealing, opting for cheaper materials might compromise the integrity and performance of the components. Quality parts can lead to improved vehicle performance and longevity, ultimately resulting in lower long-term costs for manufacturers.

When selecting automotive metal stamping parts for your project, the balance between cost efficiency and quality is paramount. A report by Grand View Research highlights that the global automotive stamping market is projected to reach USD 32.21 billion by 2025, indicating a growing demand for durable and effective parts. However, while lower costs may seem appealing, opting for cheaper materials might compromise the integrity and performance of the components. Quality parts can lead to improved vehicle performance and longevity, ultimately resulting in lower long-term costs for manufacturers.

Tips: Always conduct a thorough cost-benefit analysis when comparing suppliers. Consider the total cost of ownership, including potential warranty claims and vehicle performance metrics. Additionally, prioritize suppliers who invest in quality assurance processes, as their adherence to industry standards can minimize production delays and defects.

Moreover, implementing a just-in-time (JIT) inventory strategy can help in balancing costs and quality. According to a study published by the Society of Manufacturing Engineers, JIT can lead to a reduction in inventory holding costs by up to 30%, allowing you to invest more in high-quality stamping parts without straining your project budget. By keeping a close eye on both cost and quality, you'll be better equipped to make informed choices that enhance your project's success.