When embarking on a project that requires the use of materials, the selection of the right components is crucial for ensuring durability and functionality. One such component that often necessitates careful consideration is the Round Metal Disc. According to a recent report by Global Market Insights, the metal disc market is anticipated to reach a valuation of over $2 billion by 2026, driven by increasing applications across industries such as automotive, aerospace, and construction.

The range of available materials—ranging from stainless steel to aluminum—along with various sizes and thicknesses, adds complexity to the decision-making process. Therefore, understanding the specific requirements of your project, along with the properties of different Round Metal Discs, will allow for a more informed choice, ultimately impacting the efficiency and success of your project.

The range of available materials—ranging from stainless steel to aluminum—along with various sizes and thicknesses, adds complexity to the decision-making process. Therefore, understanding the specific requirements of your project, along with the properties of different Round Metal Discs, will allow for a more informed choice, ultimately impacting the efficiency and success of your project.

When selecting the right round metal disc for your project, it's essential to understand the various types available in the market. Metal discs come in different materials, such as stainless steel and aluminum, each offering unique benefits that cater to specific applications.

For instance, stainless steel discs are highly durable and resistant to corrosion, making them ideal for outdoor or industrial uses, while aluminum discs are lighter and more suitable for applications where weight reduction is critical.

Additionally, the thickness and diameter of the metal disc can significantly affect its performance. Thicker discs may offer greater strength but could be less versatile in certain manufacturing processes. Whether you’re looking into metal discs for construction, automotive, or artistic projects, assessing the intended use is key. As trends shift, such as the growing demand in the

CNC machining sector or the use of high-speed discs in agriculture, keeping an eye on innovations will ensure that you select the most appropriate round metal disc for your needs.

When selecting round metal discs for your project needs, there are several key factors to consider. First, the material type plays a crucial role in determining the disc's durability and suitability for specific applications. Common materials include aluminum, steel, and brass, each offering unique properties such as weight, corrosion resistance, and strength. Understanding the requirements of your project will help you choose the right material.

Another important factor is the size and thickness of the disc. Ensure that the dimensions fit seamlessly into your project design. A thicker disc may provide more strength and stability, while a thinner disc may be more suitable for lightweight applications. It’s essential to measure your space accurately and consider the tolerances required for your project to avoid any compatibility issues.

Tip: Always consult with your supplier about custom sizes or finishes, which can greatly enhance the functionality and appearance of your metal discs.

Additionally, consider the finish of the disc to align with your project's aesthetic requirements. Whether you prefer a polished, brushed, or powder-coated finish, the right choice can enhance durability and visual appeal. Be sure to weigh the importance of functionality versus aesthetic needs in your selection process to achieve the best results for your project.

Tip: Keep in mind that a high-quality finish can also affect the longevity of the metal disc, so investing in proper surface treatment can save costs in the long run.

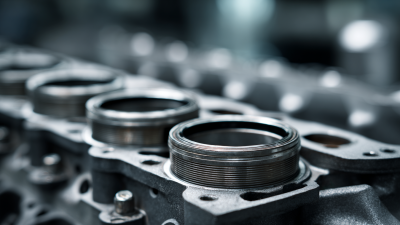

Round metal discs are utilized in a variety of applications, each with its own unique requirements. In manufacturing, these discs serve as crucial components in machinery and equipment. For instance, in the automotive industry, discs must meet stringent standards for durability and precision. The choice of material, such as stainless steel or aluminum, directly impacts the disc’s performance under stress and environmental conditions. Understanding the specific operating conditions can help in selecting the right disc for radiators, braking systems, or structural supports.

Moreover, round metal discs are integral in the art and design domain, where aesthetic and functional attributes are equally important. For applications like décor or signage, the finish and thickness of the discs play a significant role. A polished surface might be preferred for artistic pieces, while a thicker gauge could be necessary for stability in outdoor installations. Additionally, the method of fabrication—such as laser cutting or stamping—can affect the edge quality and overall look. These factors make it essential for designers and engineers to closely align their selections with the intended use of the discs, ensuring they fulfill both practical and visual requirements.

When selecting the appropriate round metal disc for your project, understanding the material properties of these discs is crucial for ensuring optimal performance. The two most commonly used materials in manufacturing round metal discs are stainless steel and aluminum. According to a report by the International Journal of Engineering Research and Applications, stainless steel offers a superior strength-to-weight ratio and excellent resistance to corrosion, making it ideal for applications in harsh environments. With a tensile strength ranging from 520 to 800 MPa, stainless steel discs are often utilized in industries such as aerospace and automotive where durability is paramount.

On the other hand, aluminum discs provide a lightweight alternative, with a density nearly one-third that of stainless steel, which can significantly reduce the overall weight of a product. A study published in the Journal of Materials Science highlights that aluminum discs possess good thermal conductivity and are easier to machine, which can lead to cost savings in production timelines. These properties make aluminum a preferred choice for applications that require frequent handling and a high level of precision, such as in the electronics or HVAC sectors. Understanding these material characteristics allows engineers and designers to make informed decisions that align with their project requirements.

When it comes to sourcing round metal discs, budgeting effectively can help ensure that your project stays on track without compromising quality. According to a recent industry report by Grand View Research, the global metal fabrication market is projected to reach $21.84 billion by 2025, indicating a growing need for cost-efficient sourcing strategies. Companies should look for suppliers that offer bulk purchasing options, which can significantly cut costs. Additionally, consider local suppliers to minimize shipping fees and expedite delivery times.

Tips for budgeting include setting a clear spending limit and factoring in hidden costs such as delivery and taxes. Establishing long-term relationships with suppliers can also yield discounts and better terms. Furthermore, conducting market research is crucial; platforms like ThomasNet provide comprehensive listings of metal disc suppliers, allowing businesses to compare prices and materials effectively. A detailed analysis of your specific requirements—such as size, thickness, and material type—will also aid in avoiding overpayments and ensuring that the discs sourced are fit for purpose.