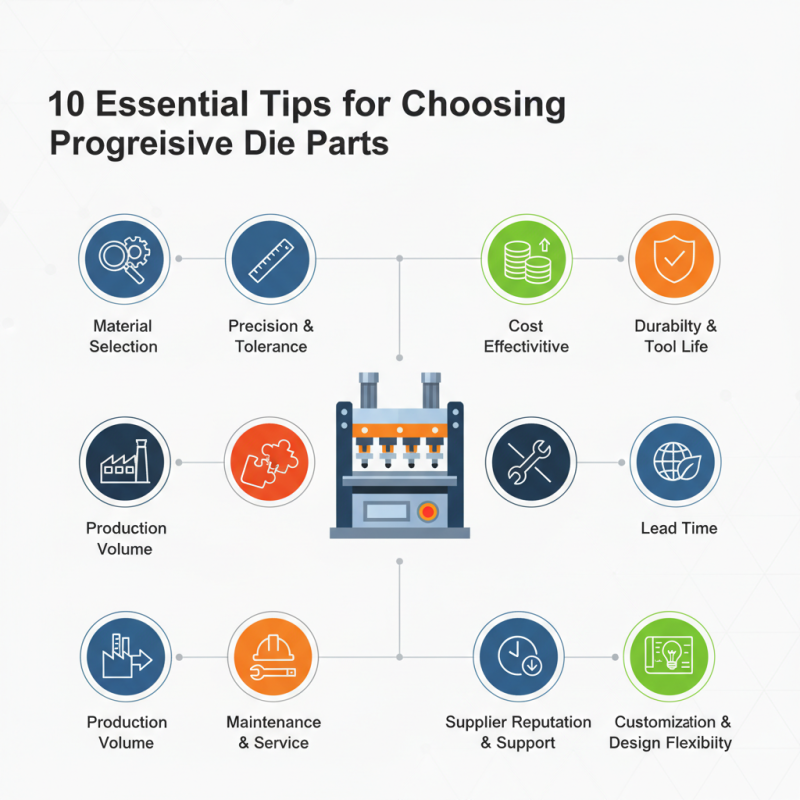

Choosing the right progressive die parts is crucial for optimizing manufacturing processes and ensuring high-quality output. In the world of manufacturing, progressive dies play a significant role by enabling the efficient fabrication of intricate components through a series of sequential operations. However, the effectiveness of these dies heavily relies on the components utilized within them. Hence, understanding how to select the appropriate progressive die parts can significantly influence production efficiency, cost-effectiveness, and overall product quality.

This guide presents ten essential tips that will help manufacturers make informed decisions when it comes to choosing progressive die parts. From understanding material choices to evaluating precision and compatibility with existing machinery, each aspect plays a pivotal role in the successful implementation of progressive dies. By mastering these considerations, manufacturing teams can enhance their operational efficiency, reduce downtime, and ultimately achieve greater competitiveness in their respective markets. Whether you are a seasoned professional or new to the manufacturing landscape, this information will serve as a valuable resource in selecting the best progressive die parts tailored to your specific needs.

Progressive die parts play a crucial role in modern manufacturing, particularly in the metal stamping industry. Understanding the basics of these parts is essential for optimizing production efficiency and achieving quality results. Progressive dies allow multiple operations to be performed in a single press stroke, which minimizes handling time and enhances precision. The design of these dies must be carefully considered, as it directly impacts both the process and the final product.

When selecting progressive die parts, it’s crucial to prioritize materials that offer durability and resistance to wear. High-quality steel is often recommended for die components to withstand the rigors of repeated use. Additionally, consider the die’s layout and the specific requirements of your manufacturing needs. A well-designed layout can significantly reduce setup times and increase production rates.

Another important tip is to pay attention to the compatibility of parts with your existing machinery. Ensuring that your chosen parts fit seamlessly into your current system can prevent costly downtime and facilitate smoother operations. It's also beneficial to consult with experts or manufacturers specializing in progressive die technologies to gain insights into the latest advancements and best practices that can enhance your production processes.

| Tip Number | Tip Description | Considerations | Benefits |

|---|---|---|---|

| 1 | Determine Material Requirements | Type of metals and thickness | Ensures proper function and durability |

| 2 | Evaluate Part Complexity | Design intricacies and features | Improves efficiency in production |

| 3 | Assess Tolerance Levels | Necessary precision for assembly | Reduces errors and part rejection rates |

| 4 | Consider Lead Times | Production timeframes and urgencies | Aligns with project deadlines |

| 5 | Select Appropriate Tooling | Tooling types based on part design | Enhances production accuracy |

| 6 | Evaluate Cost-Effectiveness | Budget constraints and options | Maximizes ROI on projects |

| 7 | Understand Maintenance Needs | Requirements for upkeep and repairs | Prolongs tool life and reduces downtime |

| 8 | Review Supplier Reputation | Feedback and reliability of providers | Ensures quality and performance |

| 9 | Incorporate New Technologies | Advanced methods in manufacturing | Boosts efficiency and innovation |

| 10 | Conduct Regular Quality Checks | Ongoing assessment protocols | Maintains standards and reduces waste |

Selecting the right progressive die parts is crucial for optimizing manufacturing processes. When assessing key specifications for your progressive die requirements, the first aspect to consider is the material compatibility. It is essential that the die parts are crafted from materials that not only withstand the specific stresses and strains of the production process but also complement the materials being processed. For instance, understanding the tensile strength and hardness of the die components can prevent premature wear and ensure longevity in production.

Another vital specification is the precision of the die parts. Variations in dimensions can lead to defective products and increased scrap rates. You should prioritize sourcing parts that meet strict tolerances and dimensional accuracy. This is particularly important for components that will be used in high-speed production environments where even minor discrepancies can result in significant losses. Finally, don’t overlook the importance of customization capabilities. A provider that can tailor die parts to meet unique design specifications will help enhance the effectiveness of your manufacturing process, allowing for flexibility and adaptability that can enhance productivity.

When selecting die parts for manufacturing, evaluating materials and durability is crucial to ensuring operational efficiency and longevity. A study by the Precision Metalforming Association indicated that nearly 30% of production downtime can be attributed to inadequately selected die components. Hence, understanding the properties of various materials, such as tool steel, aluminum, and high-performance alloys, can significantly impact the manufacturing process. Each material boasts unique characteristics that affect wear resistance, machinability, and overall performance, which ultimately influence the lifespan of the die parts.

Tip: Opt for tool steel if your manufacturing needs demand high durability and resistance to high stress. Conversely, aluminum may be suitable for less demanding applications due to its lightweight nature and cost-effectiveness, but it may not hold up well under extreme conditions.

Additionally, consider the environmental factors that your die parts will encounter. Manufacturing settings can pose various challenges such as temperature fluctuations, humidity, and abrasive materials. A market report published by SME highlighted that over 40% of companies recognize the influence of environmental conditions on die performance. Selecting materials that can withstand these factors will lead to improved durability and lower replacement costs over time.

Tip: Always conduct a thorough analysis of your specific manufacturing environment and anticipate future changes to ensure optimal material selection. Investing time into researching material properties and potential wear patterns can improve the life cycle of your die parts.

When selecting progressive die parts for your manufacturing needs, enhancing workflow and efficiency should be your top priority. A critical aspect of this process is ensuring compatibility among the parts used in the die. Using parts that work seamlessly together can significantly reduce downtime and improve overall productivity on the shop floor. For instance, opting for parts that are manufactured to closely match specifications can help minimize adjustments and facilitate quicker setups, ultimately leading to smoother operations.

One essential tip is to consider the material compatibility of die parts. Choosing parts made from materials that are suited for the specific application can help maintain quality while prolonging the lifespan of the entire die structure. Furthermore, investing in parts designed for easy assembly and disassembly can streamline maintenance processes. This ease of interchangeability not only enhances workflow but also allows for faster responses to any necessary adjustments or repairs.

Another vital point to keep in mind is to evaluate the precision and tolerances of the parts. Ensuring that each component adheres to tight tolerances will reduce the risk of discrepancies during production. This precision leads to a consistent output, which is essential in today’s fast-paced manufacturing environment. By focusing on these elements, manufacturers can enhance their workflow and achieve greater efficiency in their operations.

This chart illustrates the efficiency levels of various progressive die parts based on their compatibility and performance in manufacturing workflows. Enhanced compatibility leads to increased productivity and smoother operations.

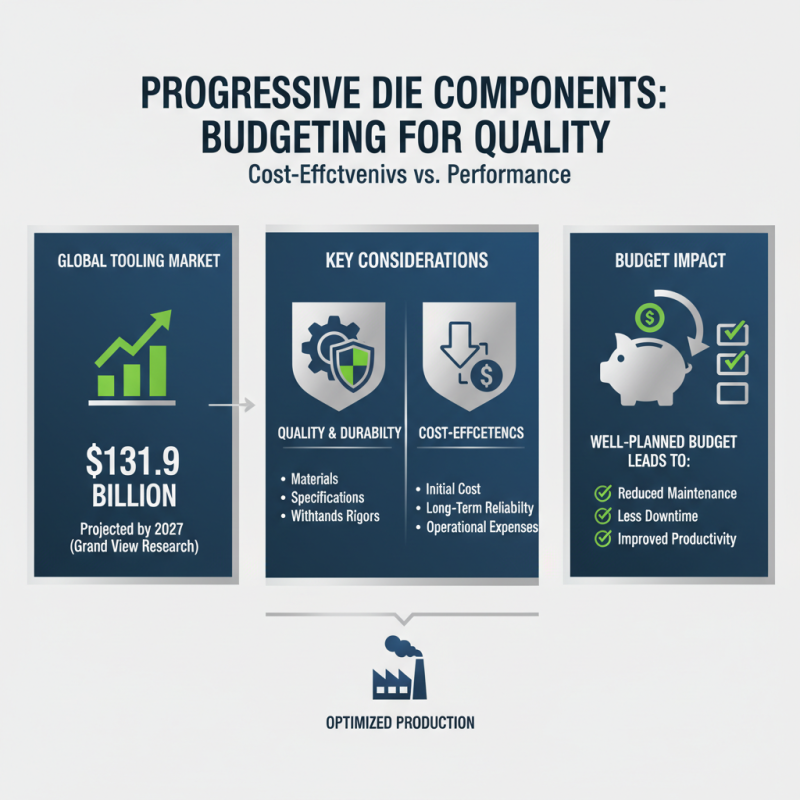

When budgeting for quality progressive die components, manufacturers must strike a balance between cost-effectiveness and performance. According to a report by Grand View Research, the global tooling market is projected to reach USD 131.9 billion by 2027, with a significant portion attributed to the demand for robust and durable die components. This statistic highlights the importance of selecting high-quality materials and specifications that can withstand the rigors of production while ensuring long-term reliability. A well-planned budget not only accommodates the initial costs but also anticipates potential savings in maintenance and downtime, ultimately contributing to improved productivity and reduced overall operational expenses.

Moreover, it’s essential to consider the lifecycle costs associated with progressive die parts. According to a study by the Society of Manufacturing Engineers, companies can see a 20-30% reduction in production costs by investing in better die components that require less frequent replacements and repairs. This underscores the necessity of viewing the acquisition of progressive die parts as an investment rather than a mere expenditure. A carefully crafted budget that emphasizes quality allows manufacturers to leverage advanced features and materials that enhance efficiency, ultimately fostering a more competitive edge in the marketplace.