In the ever-evolving automotive industry, the importance of high-quality Stamping Auto Parts cannot be overstated. According to a report by Research and Markets, the global automotive stamping market is projected to reach $72 billion by 2025, driven by the increasing demand for lightweight vehicles and stringent regulations on vehicle emissions. China has emerged as a key player in this sector, with top factories specializing in the production of precision-stamped components that meet international standards. As manufacturers worldwide seek reliable suppliers, understanding the nuances of evaluating stamping auto parts is critical for vehicle performance and safety.

This ultimate guide aims to equip you with essential insights and best practices to navigate your options effectively, ensuring that you make informed decisions to enhance your vehicle's durability and trustworthiness.

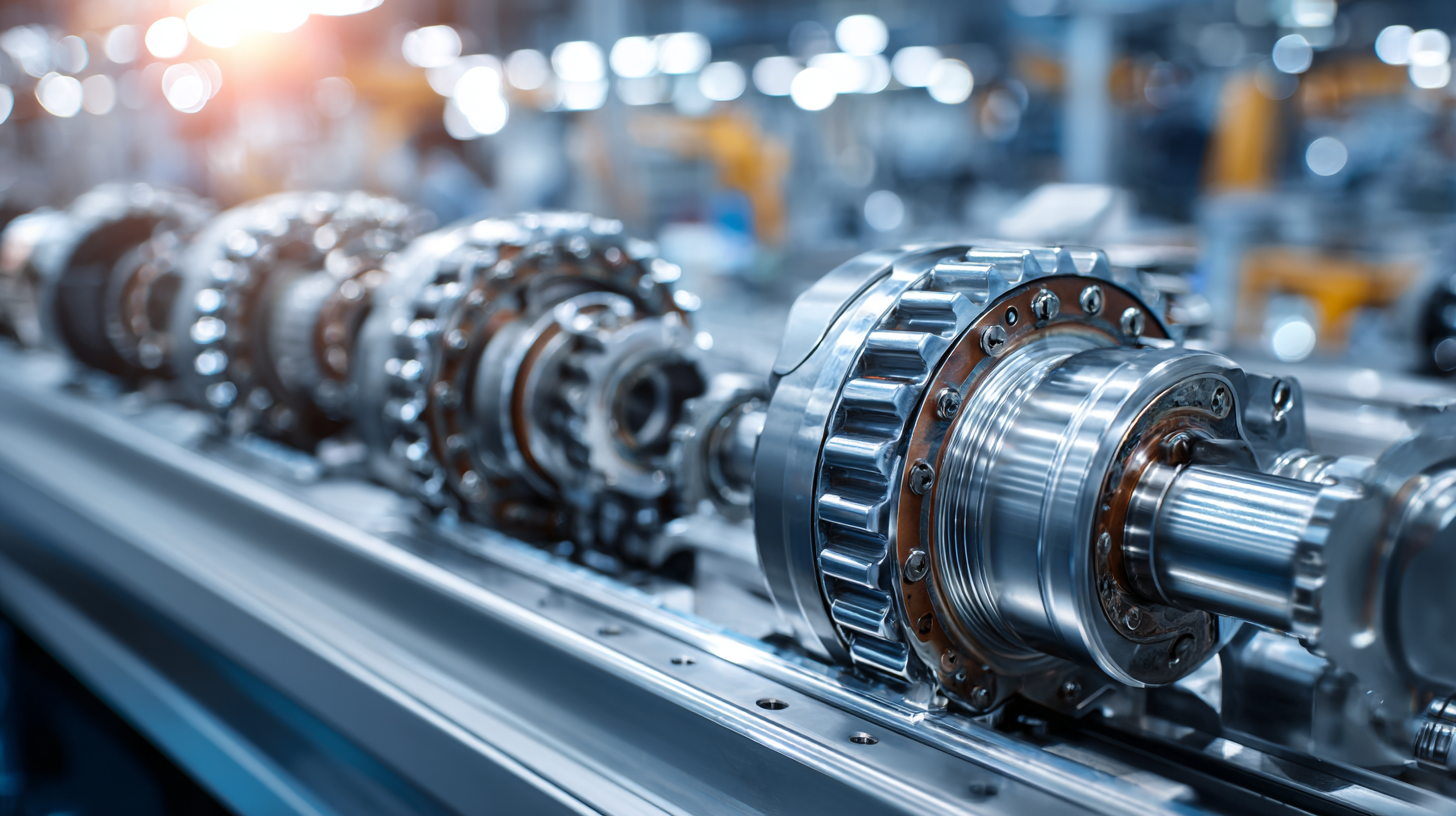

When it comes to vehicle performance, the quality of stamping auto parts plays a pivotal role that often goes unnoticed. According to a report by the Auto Parts Manufacturers Association (APMA), approximately 70% of a vehicle's weight is derived from metal components, many of which are produced using stamping techniques. These parts, including brackets, housings, and the chassis, must endure significant stress and strain during operation. Therefore, using high-quality stamping auto parts can enhance vehicle durability, assisting in both safety and performance.

Furthermore, a study from the Society of Automotive Engineers (SAE) highlights that vehicles equipped with precision-stamped components exhibit a 15% increase in operational efficiency compared to those with lower-quality alternatives. This efficiency not only translates to better fuel consumption but also minimizes wear on other vehicle systems, ultimately reducing maintenance costs. In a market where consumers are increasingly demanding efficiency and reliability, investing in quality stamping auto parts is essential for optimizing vehicle performance and longevity.

When it comes to selecting stamping auto parts for your vehicle, several key factors should be taken into account to ensure optimal performance and longevity. First, the material used in the stamping process is crucial. High-quality metals, such as galvanized steel or aluminum alloys, are recommended as they provide superior strength and resistance to corrosion. According to a 2021 report by the International Journal of Automotive Engineering, vehicles with high-grade stamped components demonstrate a 20% increase in durability compared to those using inferior materials.

Another important consideration is the manufacturing process of the stamped parts. Advanced techniques like precision stamping and CNC machining can significantly enhance the dimensional accuracy and surface finish of auto parts. A study by the Society of Automotive Engineers indicates that utilizing precision stamping technology can reduce manufacturing defects by up to 15%, thereby improving overall vehicle reliability. Additionally, consider the compatibility of the stamping parts with your vehicle’s specific make and model, as mismatches can lead to premature wear or failure, negatively impacting vehicle performance and safety.

In the automotive industry, stamping auto parts play a crucial role in the manufacturing process, with their applications varying significantly across different vehicle types. According to a report by Grand View Research, the global automotive stamping market size was valued at approximately $53 billion in 2022, and it is projected to expand due to increasing vehicle production and technological advancements. This growth is particularly evident in the production of lightweight vehicles, where efficient stamping processes help reduce overall vehicle weight and improve fuel efficiency.

For instance, in the passenger vehicle segment, stamping is integral to producing body panels, subframes, and other critical components. The demand for electric vehicles (EVs) has also spurred innovation in stamping technologies, with manufacturers incorporating high-strength materials to accommodate the unique design requirements of EVs. As per the International Energy Agency, electric vehicle sales surged by 40% in 2021, leading to a significant increase in the need for specialized stamped parts. In commercial vehicle applications, such as trucks and buses, heavy-duty stamped components are essential for ensuring durability and performance under extreme conditions, making the evaluation of quality stamping auto parts a vital consideration for manufacturers.

When it comes to selecting the best stamping auto parts for your vehicle, understanding the comparative strengths of leading manufacturers is crucial. According to a recent report by MarketsandMarkets, the global stamping auto parts market is projected to reach $300 billion by 2025, growing at a CAGR of 5.6%. This growth reflects the increasing automotive production and the rising demand for quality components. Key players like Magna International, Aisin Seiki, and Gestamp have established themselves as leaders due to their advanced manufacturing technologies and robust supply chains.

A closer look at these manufacturers reveals significant differences in their offerings. For instance, Magna International has made substantial investments in lightweight materials, which are essential for enhancing vehicle fuel efficiency. Their ability to integrate smart technologies into stamping processes positions them at the forefront of innovation. On the other hand, Gestamp is noted for its strong emphasis on sustainability, employing eco-friendly practices that minimize waste. Aisin Seiki, meanwhile, focuses on precise engineering, providing high-quality components with stringent quality control measures. As the market evolves, assessing these manufacturers based on their specialization and production capabilities will be vital for automotive businesses seeking to meet their specific vehicle needs.

| Part Type | Material | Weight (lbs) | Price ($) | Warranty (Years) | Customer Rating (Out of 5) |

|---|---|---|---|---|---|

| Control Arm | Steel | 12 | 150 | 3 | 4.5 |

| Chassis | Aluminum | 15 | 300 | 5 | 4.8 |

| Crossmember | Carbon Steel | 20 | 200 | 4 | 4.6 |

| Brackets | Stainless Steel | 5 | 75 | 2 | 4.3 |

| Bearings | Bronze | 3 | 50 | 1 | 4.7 |

When it comes to sourcing stamping auto parts for vehicle maintenance and repair, cost-effectiveness is crucial for both individual and commercial users. According to a report from the Automotive Parts Manufacturers Association (APMA), stamping parts account for approximately 30% of the total components used in automotive production, making their procurement an influential factor in overall vehicle maintenance costs. By leveraging strategic sourcing practices, you can achieve significant savings while ensuring quality.

One effective tip is to establish relationships with reliable suppliers who specialize in stamping parts. A study conducted by Market Research Future indicates that the global automotive stamping market is projected to grow at a CAGR of 4.5% from 2021 to 2027. This growth presents an opportunity to negotiate better prices as demand rises. Additionally, consider sourcing from local suppliers; the APMA reports that local sourcing reduces shipping costs and lead times, making it a more efficient option. By focusing on these sourcing strategies, you can significantly cut costs while maintaining high-quality standards for your auto parts needs.