Hydraulic seals play a crucial role in various industries, ensuring efficiency and safety in hydraulic systems. According to Dr. John Smith, a renowned expert in fluid mechanics, “Hydraulic seals are the unsung heroes of machinery.” This statement highlights the importance of understanding how these components function.

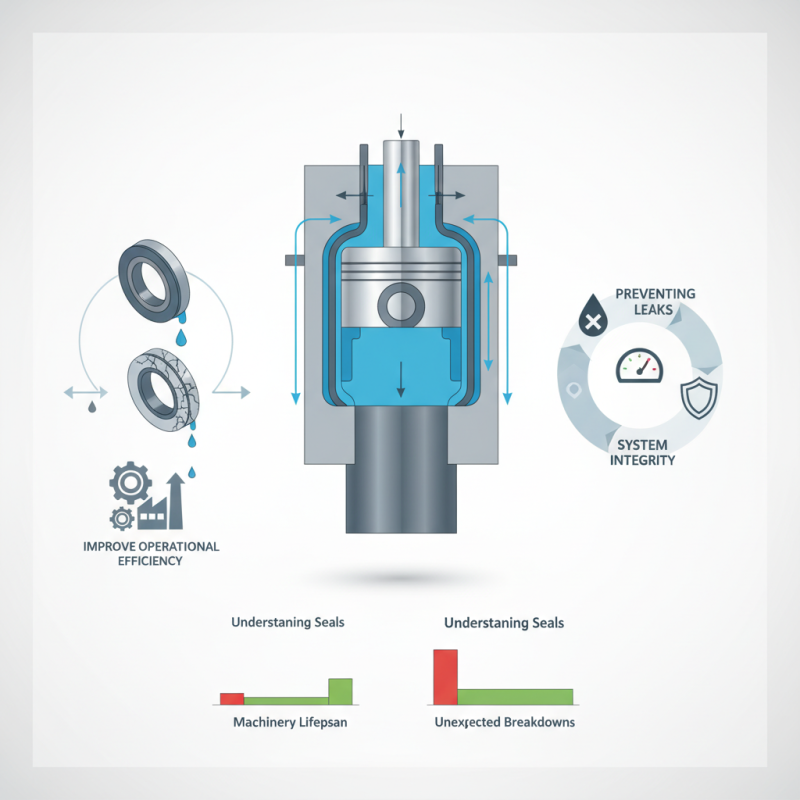

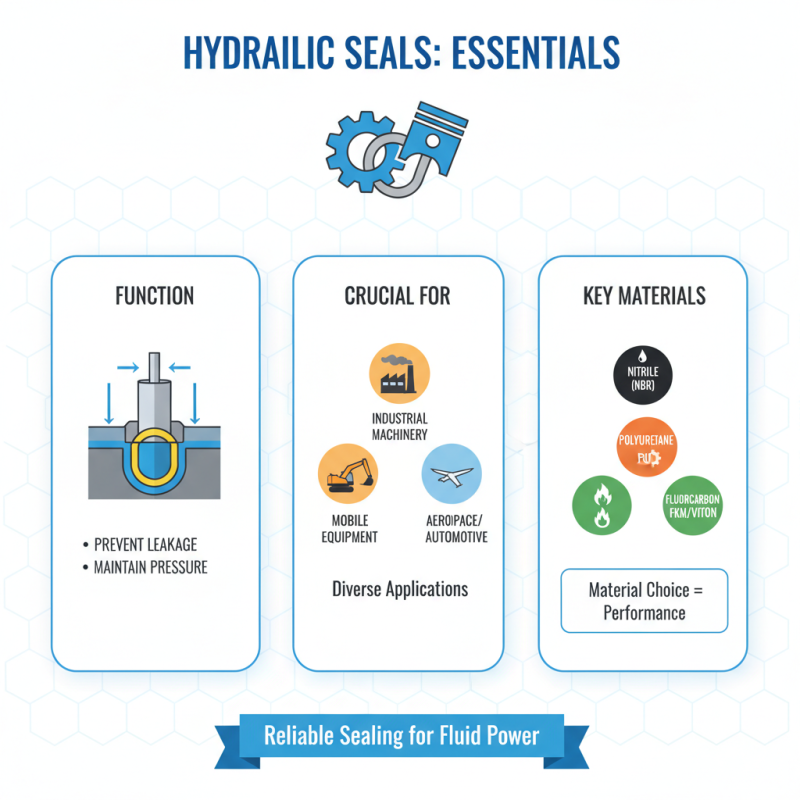

The design and material selection of hydraulic seals significantly affect their performance. They prevent fluid leaks and maintain pressure, which is essential for system integrity. Without proper seals, machinery can suffer from catastrophic failures.

Despite their importance, many overlook these components. There is often a lack of awareness regarding their maintenance and replacement needs. This oversight can lead to reduced machinery lifespan and increased costs. Understanding hydraulic seals can ultimately improve operational efficiency and reduce unexpected breakdowns.

Hydraulic seals play a crucial role in various industrial applications. These seals are specifically designed to prevent fluid leakage in hydraulic systems. They create a barrier that maintains pressure while allowing movement. The effectiveness of a hydraulic seal is essential for operational efficiency.

Understanding hydraulic seals requires knowledge of their components. Typically, they are made from materials like rubber or thermoplastics. These materials can withstand high pressure and temperature changes. According to industry reports, nearly 70% of hydraulic system failures are linked to seal issues. This statistic underscores the importance of proper selection and maintenance of seals.

The performance of hydraulic seals can be influenced by factors like fluid type and environment. For instance, exposure to abrasive materials can degrade seals over time. Regular inspections are crucial. It is vital to ensure seals are in good condition. Failing to do so can lead to costly downtimes. Data suggests that even minor leaks can result in significant product loss. Many operators overlook this aspect, which can be detrimental. Thus, securing a reliable seal is not just technical; it’s a strategic necessity.

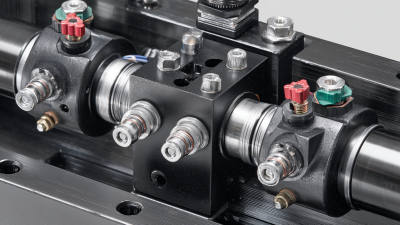

Hydraulic seals are crucial components in machinery that prevents fluid leakage. They help maintain pressure and ensure efficient operation. Understanding different types of hydraulic seals can help in choosing the right one for your application.

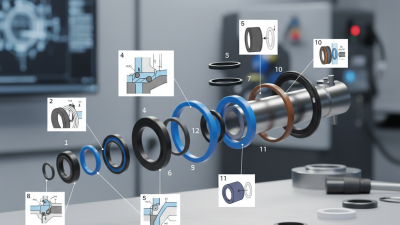

There are several primary types of hydraulic seals. O-rings are common and versatile. They are used in various applications due to their simple design. U-cup seals provide excellent sealing performance in dynamic conditions. They work well in hydraulic cylinders. Rod seals and piston seals are also vital. They ensure that fluid stays contained, preventing leaks.

Tip: Always consider material compatibility when selecting seals. Different fluids can degrade materials. Regular inspections help identify wear and tear. This is vital in preventing unexpected failures.

Understanding the specific needs of each application is key. Some seals may require maintenance or replacement sooner than others. Don’t rush your choices. Take time to evaluate the demands of your system. A small mistake can lead to significant issues.

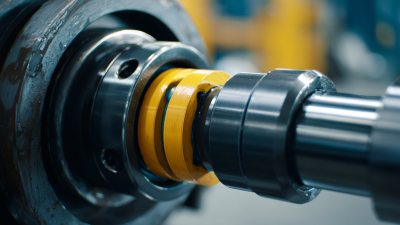

Hydraulic seals are crucial components in fluid systems. They create a barrier to prevent leaks between moving parts. These seals operate under pressure and help maintain system efficiency. A well-functioning hydraulic seal minimizes fluid loss and protects the environment from contamination.

When hydraulic systems work, the seals experience a lot of stress. They must endure high pressures and varying temperatures. Friction can wear them down over time. If a seal fails, it can lead to significant problems. For example, hydraulic fluid can leak, affecting performance and safety. Regular maintenance is necessary to identify potential issues before they escalate.

It's interesting to note how different types of seals serve specific functions. Some seals are designed for static applications, while others manage dynamic situations. Each type has its unique materials and design considerations. Yet, sometimes the wrong choice leads to failures. Understanding the context of use is vital. Seals must match the specific demands of the system for optimal performance.

| Type of Hydraulic Seal | Material | Application | Operating Pressure (MPa) | Temperature Range (°C) |

|---|---|---|---|---|

| O-Ring Seals | Nitrile Rubber | Pumps and Cylinders | 20 - 35 | -40 to 100 |

| U-Cup Seals | Polyurethane | Hydraulic Cylinders | 30 - 50 | -30 to 80 |

| V-Seals | Elastomer | Rotary Applications | 15 - 25 | -20 to 90 |

| Rod Seals | PTFE | Industrial Machines | 40 - 80 | -50 to 120 |

| Backup Rings | Hard Plastic | High Pressure Systems | 50 - 100 | -40 to 130 |

Hydraulic seals play a crucial role in various applications. They prevent fluid leakage and maintain pressure within hydraulic systems. The choice of materials is vital for effective seal performance. Common materials used in hydraulic seal manufacturing include Nitrile, Polyurethane, and Fluorocarbon.

Nitrile rubber is a popular choice for seals. It offers excellent resistance to oils and fuels. It can withstand harsh conditions but has limitations against heat and ozone. Polyurethane provides superior wear resistance. It is ideal for dynamic applications. However, it can become brittle over time. Fluorocarbon, known for its high-temperature stability, is often used in aggressive environments. Yet, it may not be the best choice for low-pressure applications.

Tips: Regularly check seals for wear and tear. Replace them promptly to avoid system failures. Using the right seal material for specific conditions is crucial. Always consider temperature and chemical exposure when selecting materials. This can prolong the life of seals and improve overall system efficiency. Understanding these materials helps enhance hydraulic system performance.

Hydraulic seals play a critical role in machinery. However, they often face common issues that can lead to failures. One frequent problem is leakage. If seals are worn or damaged, hydraulic fluid can escape. This not only leads to inefficiency but can also cause safety hazards. Regular inspections are essential to detect early signs of wear.

Maintenance of hydraulic seals involves several steps. Keeping the system clean is paramount. Contaminants can deteriorate seals quickly. Additionally, monitoring pressure levels is important. Excessive pressure can stress the seals, leading to premature failure. Replacing seals at the first sign of wear is wiser than waiting. It’s a costly mistake to ignore minor issues.

Temperature fluctuations can also affect seal performance. High temperatures may cause seals to soften or deform. On the other hand, extreme cold can make seals brittle. Proper material selection for seals is crucial. In some cases, professionals might recommend upgrading to better materials. Thoughtful decisions during maintenance can extend the lifespan of the seals and improve overall efficiency.