In the rapidly evolving landscape of manufacturing, understanding the intricacies of Progressive Die Parts has become increasingly crucial for optimizing production efficiency and enhancing product quality. According to a report by MarketsandMarkets, the global die casting market is projected to reach USD 104.75 billion by 2025, growing at a CAGR of 5.0%. This surge is driven by the rising demand for lightweight and intricate components, which are often produced through progressive die stamping processes. These parts are essential in various industries, including automotive and electronics, where precision and speed are paramount. The adoption of advanced materials and innovative design in Progressive Die Parts not only facilitates complex shapes but also reduces manufacturing costs, making it a key focus area for manufacturers aiming to stay competitive in today's market.

Progressive die parts play a crucial role in modern manufacturing, significantly enhancing the efficiency and precision of metal forming processes. One of the key characteristics of these parts is their ability to perform multiple operations in a single stroke. This design minimizes the need for separate tools and setups, reducing manufacturing time and labor costs. Consequently, businesses benefit from increased productivity and a streamlined workflow that allows for rapid production of complex components.

Another important feature of progressive die parts is their adaptability to various materials and thicknesses. These dies are engineered to handle a range of metals, enabling manufacturers to produce parts with different specifications without compromising quality. Additionally, progressive dies are built to maintain tight tolerances, ensuring that each component meets precise design requirements. This capability not only enhances product consistency but also reduces scrap and waste, contributing to more sustainable manufacturing practices. As industries continue to evolve, the importance of understanding and integrating the key characteristics of progressive die parts will be vital for maintaining competitive advantages in the market.

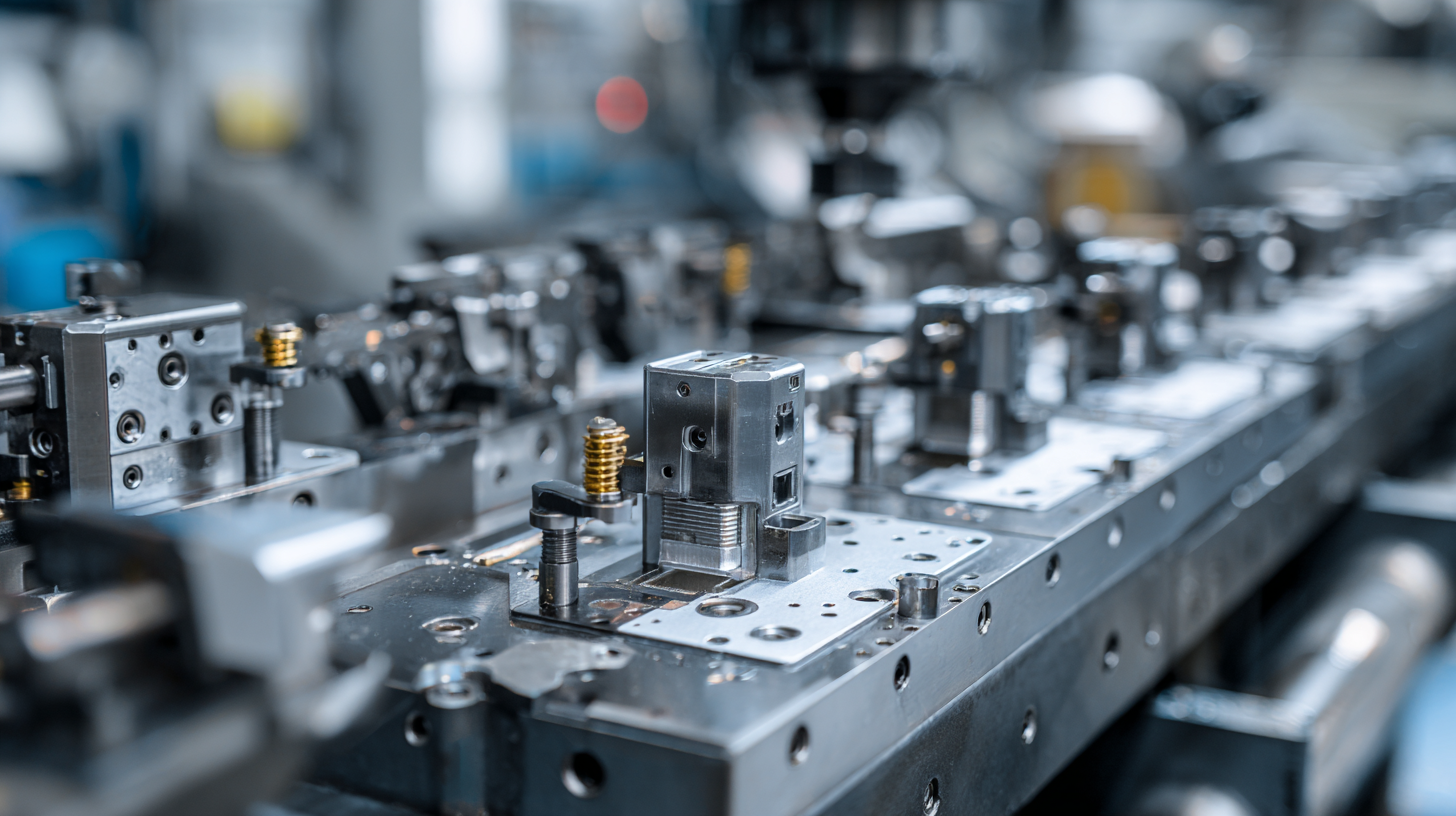

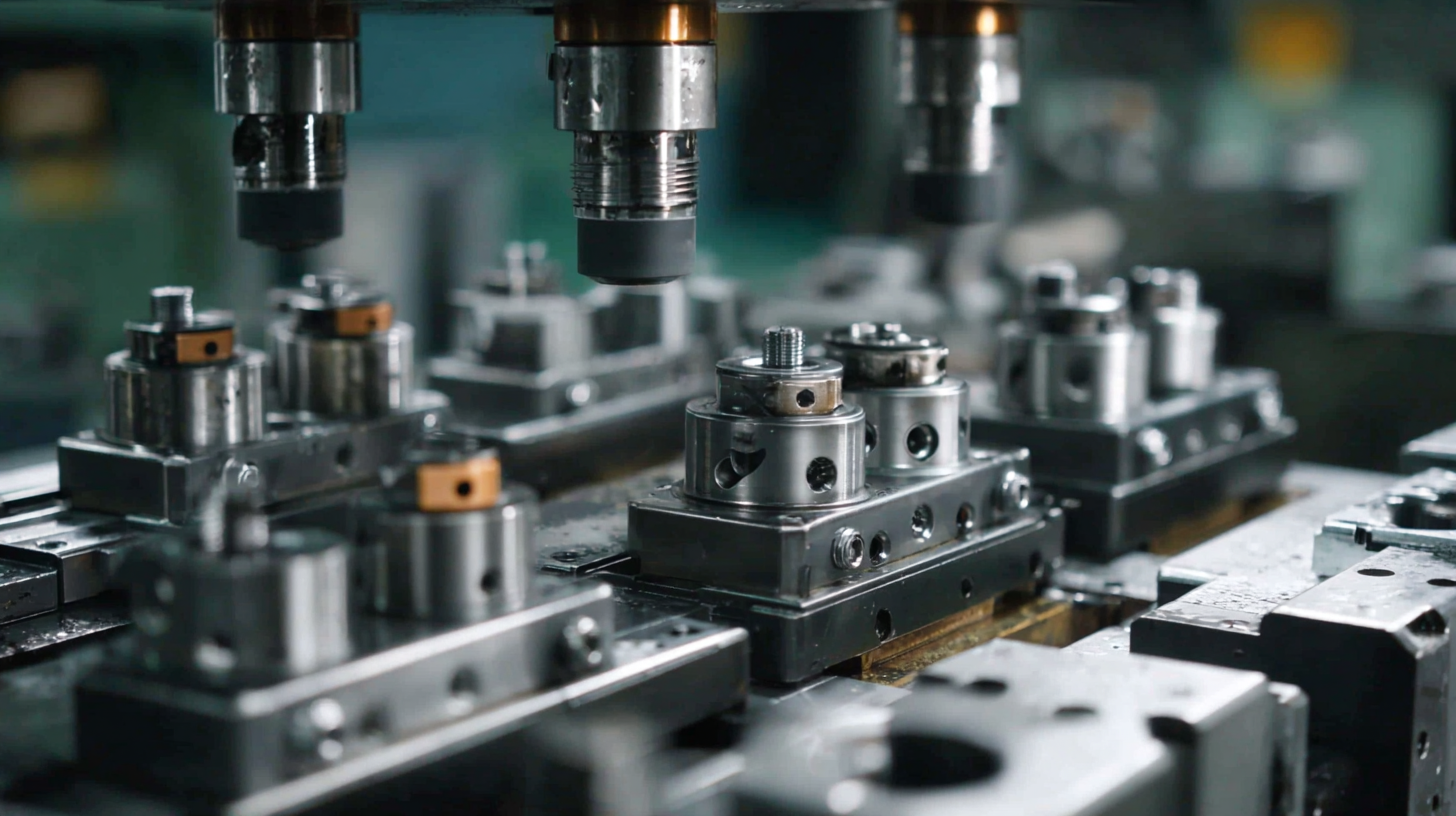

In modern manufacturing processes, progressive die parts play a crucial role in enhancing efficiency and precision. These parts are specifically designed to perform a sequence of operations with the material in a single setup, minimizing the need for multiple tools and setups. Among the various types of progressive die parts, the feed shoe and die block are fundamental.

The feed shoe accurately controls the material's movement into the die, ensuring that the metal is positioned correctly for each stamping operation. Meanwhile, the die block houses the cutting and forming components, allowing for complex shapes to be produced with precision.

The feed shoe accurately controls the material's movement into the die, ensuring that the metal is positioned correctly for each stamping operation. Meanwhile, the die block houses the cutting and forming components, allowing for complex shapes to be produced with precision.

Another essential type of progressive die part is the pilot, which serves to guide the material into the necessary alignment for operations. Pilots maintain consistency and reduce the chances of errors during the process. Additionally, the stripper plate plays a vital role in the removal of the finished part from the die after each cycle, enhancing the efficiency of the production line. Understanding these distinct components and their functions is vital for manufacturers striving for higher productivity and lower operational costs in their assembly processes.

When comparing progressive die parts with other die types, such as single-use and transfer dies, the differences in efficiency and production capabilities become evident. Progressive dies are designed to perform multiple operations sequentially in one stroke, which significantly reduces setup time and enhances productivity. In contrast, single-use dies may only execute one operation per cycle, making them less efficient for high-volume production. This ability to handle various tasks in a single machine run presents a significant advantage for manufacturers aiming for operational speed and cost-effectiveness.

Moreover, transfer dies are often utilized for large or complex parts that require material to be moved between different workstations. While transfer dies provide flexibility in shape and function, they require additional handling and machinery, increasing the production time and overall cost. Progressive dies, on the other hand, streamline the process by keeping all operations within a single die setup, minimizing the risk of part handling errors and ensuring a higher level of precision. This integration ultimately results in a more efficient workflow and higher quality in the finished parts, making progressive dies an attractive option for many manufacturing applications.

When designing efficient progressive die parts, several critical considerations must be at the forefront of the development process. A pivotal aspect of progressive die design is the reverse engineering approach: starting from the final part shape and retracing steps back to the flat blank. This ensures that all features of the part are accurately translated and accounted for, allowing for precise manufacturing outcomes. The design should facilitate smooth transitions between stations, minimizing material movement and optimizing the workflow throughout the stamping process.

Additionally, material selection plays a vital role in the efficiency of progressive die parts. The choice of material should not only align with the desired mechanical properties of the final component but also enhance manufacturability. Understanding the specific requirements of the material, such as its formability and strength, can help in developing dies that withstand the rigors of high-speed production while maintaining quality. Proper analysis and testing during the design phase ensure that progressive dies can operate effectively and yield high volumes of parts with minimal downtime and waste.

| Feature | Description | Design Consideration | Impact on Efficiency |

|---|---|---|---|

| Material Selection | Choosing the right material for die parts is crucial for durability and performance. | Evaluate material properties such as tensile strength and wear resistance. | Improves die life and reduces downtime for maintenance. |

| Precision Engineering | High precision in the design ensures better fit and functionality of die components. | Use advanced CAD tools and CNC machining for accurate dimensions. | Enhances product quality and reduces material wastage. |

| Tooling Complexity | The complexity of the tooling affects the die's manufacturing and maintenance. | Simplify designs where possible to facilitate easier manufacturing and repair. | Reduces costs and leads to shorter production cycles. |

| Cooling Systems | Efficient cooling systems help manage temperature during high-speed manufacturing. | Design cooling channels that enhance heat dissipation. | Increases operational speed and reduces thermal stress on the die. |

| Surface Treatment | Surface treatments can improve wear resistance and prevent corrosion. | Select appropriate treatments based on application and environment. | Extends die service life and enhances product quality. |

Progressive die parts play a crucial role in various manufacturing industries due to their ability to efficiently produce high volumes of precision metal components. One of the primary applications of progressive die parts is in the automotive industry, where they are used to create intricate pieces such as brackets, fasteners, and clips. These parts must meet strict quality and dimensional tolerances, making progressive die stamping an ideal choice for achieving consistency and reducing production time. By utilizing multiple operations within a single die, manufacturers can significantly streamline their processes and lower costs.

Another key sector benefiting from progressive die parts is the electronics industry. Here, components such as connectors, housings, and heat sinks are manufactured with precision and speed. The ability to produce complex geometries and detailed features in high volumes suits the rapidly evolving market demands for consumer electronics. Furthermore, as industries strive for sustainability, progressive dies also contribute to waste reduction by maximizing material usage, leading to more environmentally friendly manufacturing practices. Overall, the versatility of progressive die parts is reshaping production across numerous sectors, driving innovation and efficiency.