In the competitive landscape of manufacturing, optimizing production efficiency is paramount, and understanding the functionality of

Progressive Die Parts can lead to significant advancements. According to the

2022 Manufacturing Benchmarking Report by the National Association of Manufacturers, companies that effectively utilize

advanced tooling techniques, including the integration of

progressive dies, report up to 30% reductions in production time and a 25% increase in overall output.

These striking improvements stem from the ability of

Progressive Die Parts to perform multiple operations in a single pass, thereby minimizing material waste and labor costs.

By delving into the intricacies of these parts—ranging from the design process to the operational parameters—manufacturers can unlock enhanced performance and productivity.

This guide elucidates essential insights and strategies for leveraging

Progressive Die Parts in your production line, paving the way for greater efficiency and profitability.

In the competitive landscape of manufacturing, optimizing production efficiency is paramount, and understanding the functionality of

Progressive Die Parts can lead to significant advancements. According to the

2022 Manufacturing Benchmarking Report by the National Association of Manufacturers, companies that effectively utilize

advanced tooling techniques, including the integration of

progressive dies, report up to 30% reductions in production time and a 25% increase in overall output.

These striking improvements stem from the ability of

Progressive Die Parts to perform multiple operations in a single pass, thereby minimizing material waste and labor costs.

By delving into the intricacies of these parts—ranging from the design process to the operational parameters—manufacturers can unlock enhanced performance and productivity.

This guide elucidates essential insights and strategies for leveraging

Progressive Die Parts in your production line, paving the way for greater efficiency and profitability.

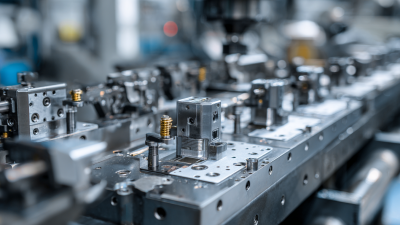

Progressive die parts are integral in manufacturing processes, particularly when it comes to producing high volumes of components efficiently. Understanding the basics of these parts starts with recognizing their role in shaping and cutting materials. The progressive die operates through a series of stations, each performing a specific operation, which allows for continuous feeding of material and minimizes waste. This method not only streamlines production but also enhances precision and consistency in the final product.

Progressive die parts are integral in manufacturing processes, particularly when it comes to producing high volumes of components efficiently. Understanding the basics of these parts starts with recognizing their role in shaping and cutting materials. The progressive die operates through a series of stations, each performing a specific operation, which allows for continuous feeding of material and minimizes waste. This method not only streamlines production but also enhances precision and consistency in the final product.

Tips: To optimize your use of progressive die parts, ensure that you regularly assess the wear and tear of the dies. This can help prevent any unexpected failures during production. Additionally, consider investing in training for your team regarding die maintenance and proper handling techniques to extend the lifespan of your equipment.

By grasping the functionality of progressive die parts, manufacturers can identify areas for improvement and implement strategies that enhance productivity. Make use of simulation software to design and tweak die layouts before actual production, enabling you to optimize the process while reducing setup times and costs.

Understanding the key components in progressive dies is crucial for optimizing production efficiency. Progressive dies consist of several parts such as the die body, punch, and feed system, each playing a significant role in the stamping process. According to a recent report by the Precision Metalforming Association (PMA), companies that implement robust die designs improve their production rates by up to 30%. The die body provides the foundation and stability for the entire mechanism, while the punch must be precisely calibrated for accurate material removal, ensuring that parts are made to specification with minimal waste.

Moreover, the efficiency of the feed system directly affects the speed and quality of production. A well-maintained feed system can reduce material handling times by as much as 25%, as indicated by industry data from the Fabricators & Manufacturers Association (FMA). In addition, the choice of materials for the die components influences their durability and operational lifespan. Utilizing high-quality steel alloys, for instance, can enhance wear resistance, leading to fewer die changes and reduced downtime. By focusing on these key components and their functionality, manufacturers can achieve optimal performance from their progressive dies, ultimately resulting in a more streamlined production process.

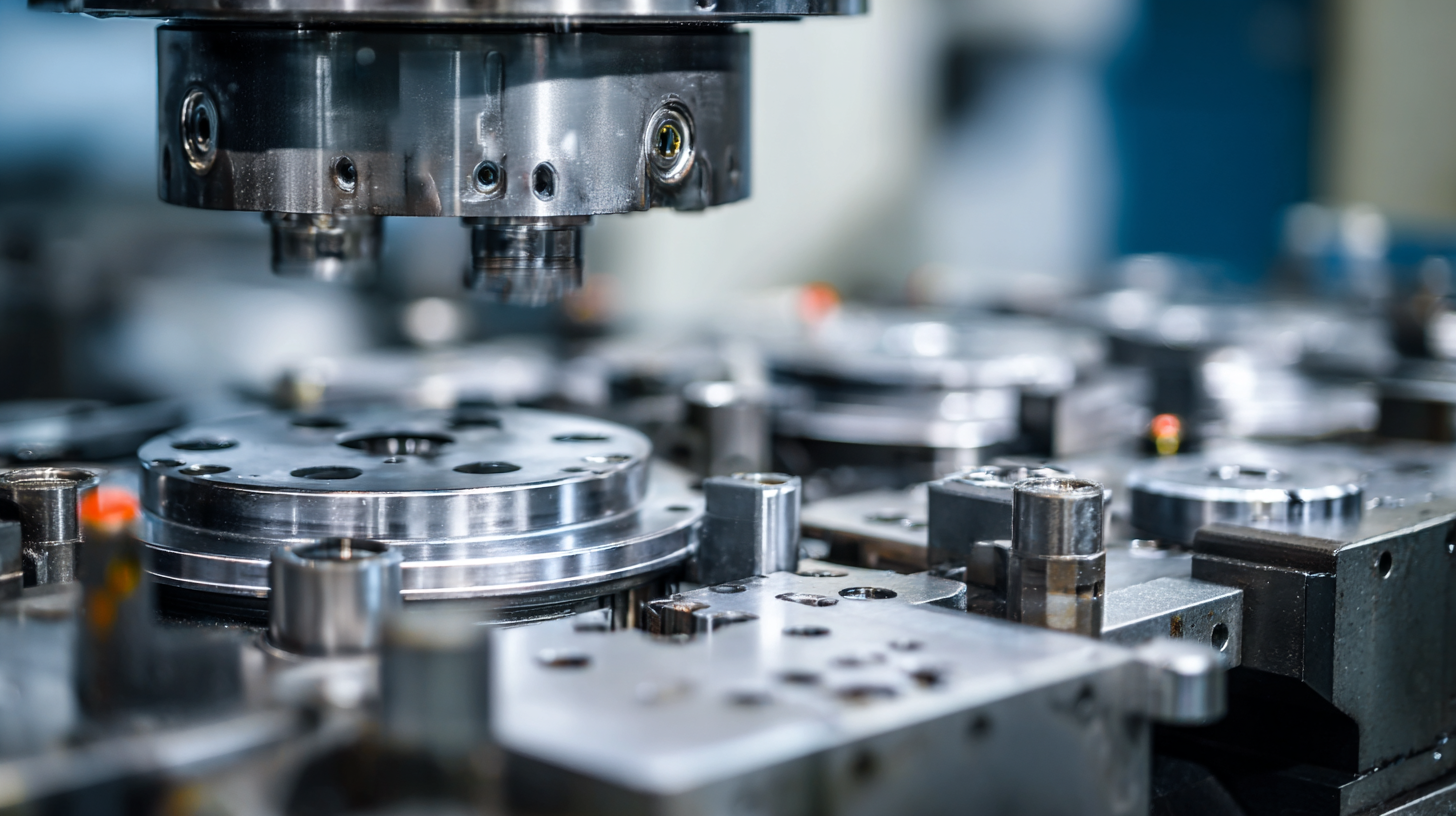

Progressive die stamping is a crucial method in manufacturing, particularly for producing high-volume metal parts with precise dimensions. To enhance production efficiency using die parts, manufacturers can leverage several techniques. According to a report by the Precision Metalforming Association, companies implementing advanced die technologies can improve their productivity by up to 30%. This is achievable by optimizing the die layout to minimize cycle times and reduce material waste.

Moreover, regular maintenance of die components plays a significant role in sustaining production efficiency. A study published in the Journal of Manufacturing Processes highlights that proper upkeep can extend the lifespan of die parts by 25%, reducing the frequency of costly replacements. Additionally, employing real-time monitoring systems can provide valuable insights into the operational status of die parts, allowing for proactive maintenance that further decreases downtime. By integrating these techniques, manufacturers not only enhance their production capabilities but also contribute to overall cost savings and improved product quality.

Progressive dies are a crucial component in manufacturing, facilitating the mass production of complex metal components. However, many manufacturers face common challenges in their use, such as tool wear, alignment issues, and material defects, which can lead to increased costs and downtimes. According to a recent industry report from the Fabricators & Manufacturers Association, improper die maintenance can result in up to a 15% reduction in overall efficiency, emphasizing the need for regular assessments and timely interventions.

To overcome these challenges, it's essential to implement best practices in die maintenance and operation. This includes comprehensive training for operators and maintenance personnel, helping them to recognize early signs of wear or misalignment. Moreover, the use of advanced monitoring technologies can provide real-time data on die performance, enabling proactive measures that reduce costs and enhance productivity. As the manufacturing sector becomes more tech-driven, embracing innovation will not only solve existing problems but also open avenues for improved efficiency and product quality. By understanding and addressing these common challenges, manufacturers can significantly optimize their operations with progressive die parts.

Maintaining progressive die parts is crucial for ensuring efficient production processes and minimizing downtime. According to a report by the National Tooling and Machining Association, improper maintenance can lead to a 30% reduction in productivity. Regular inspections and timely maintenance of die components can help avoid these costly interruptions. It's essential to adopt best practices such as daily cleaning, lubrication, and checking for wear and tear. Implementing a systematic maintenance schedule based on the manufacturer's specifications can save manufacturers up to 50% in replacement costs over time.

Moreover, understanding the specific functionalities of each die part can enhance maintenance efforts. A study from the Precision Metalforming Association highlights that recognizing symptoms of wear—such as unusual noises or inconsistent part quality—can lead to early diagnosis and intervention. Techniques like preventative maintenance training and the use of advanced monitoring systems can also play a pivotal role in prolonging the lifespan of die parts. Emphasizing these best practices not only optimizes production but also fosters a culture of care and efficiency in manufacturing settings.

| Part Name | Functionality | Common Issues | Maintenance Tips | Expected Lifespan |

|---|---|---|---|---|

| Punch | Used for cutting material | Wear and tear, chipping | Regular sharpening and inspection | 500,000 cycles |

| Die Block | Holds die components securely | Cracking or misalignment | Routine cleaning and re-aligning | 2 million cycles |

| Guide Pins | Guarantee precise alignment | Bending or galling | Lubrication and visual inspections | 1 million cycles |

| Strippers | Removes finished parts from die | Sticking or deformity | Adjust tension and clean regularly | 800,000 cycles |

| Holding Blocks | Secure part during cutting | Loosening or damage | Check screws and fasteners | 1.5 million cycles |