In the realm of product design and manufacturing, the utilization of Stamped Sheet Metal has emerged as a pivotal factor contributing to enhanced durability and overall design superiority. According to the 2024 Industry Report by the Metal Stamping Association, approximately 60% of manufacturers are increasingly adopting stamped sheet metal due to its ability to achieve precise tolerances and complex geometries, vital for modern design requirements. The inherent properties of stamped sheet metal, such as high strength-to-weight ratios and excellent corrosion resistance, make it an ideal choice for industries ranging from automotive to aerospace, where reliability and longevity are paramount.

In the realm of product design and manufacturing, the utilization of Stamped Sheet Metal has emerged as a pivotal factor contributing to enhanced durability and overall design superiority. According to the 2024 Industry Report by the Metal Stamping Association, approximately 60% of manufacturers are increasingly adopting stamped sheet metal due to its ability to achieve precise tolerances and complex geometries, vital for modern design requirements. The inherent properties of stamped sheet metal, such as high strength-to-weight ratios and excellent corrosion resistance, make it an ideal choice for industries ranging from automotive to aerospace, where reliability and longevity are paramount.

As the push for sustainability and cost-efficiency intensifies, stamped sheet metal stands out as a material that not only meets stringent performance standards but also supports eco-friendly manufacturing practices. The latest market analysis indicates that the global market for stamped metal components is projected to reach USD 300 billion by 2025, reflecting a substantial shift towards this technology in product design. With advancements in stamping techniques and technologies, companies can leverage stamped sheet metal to create innovative products that are both lightweight and robust, ensuring they maintain a competitive edge in an ever-evolving marketplace.

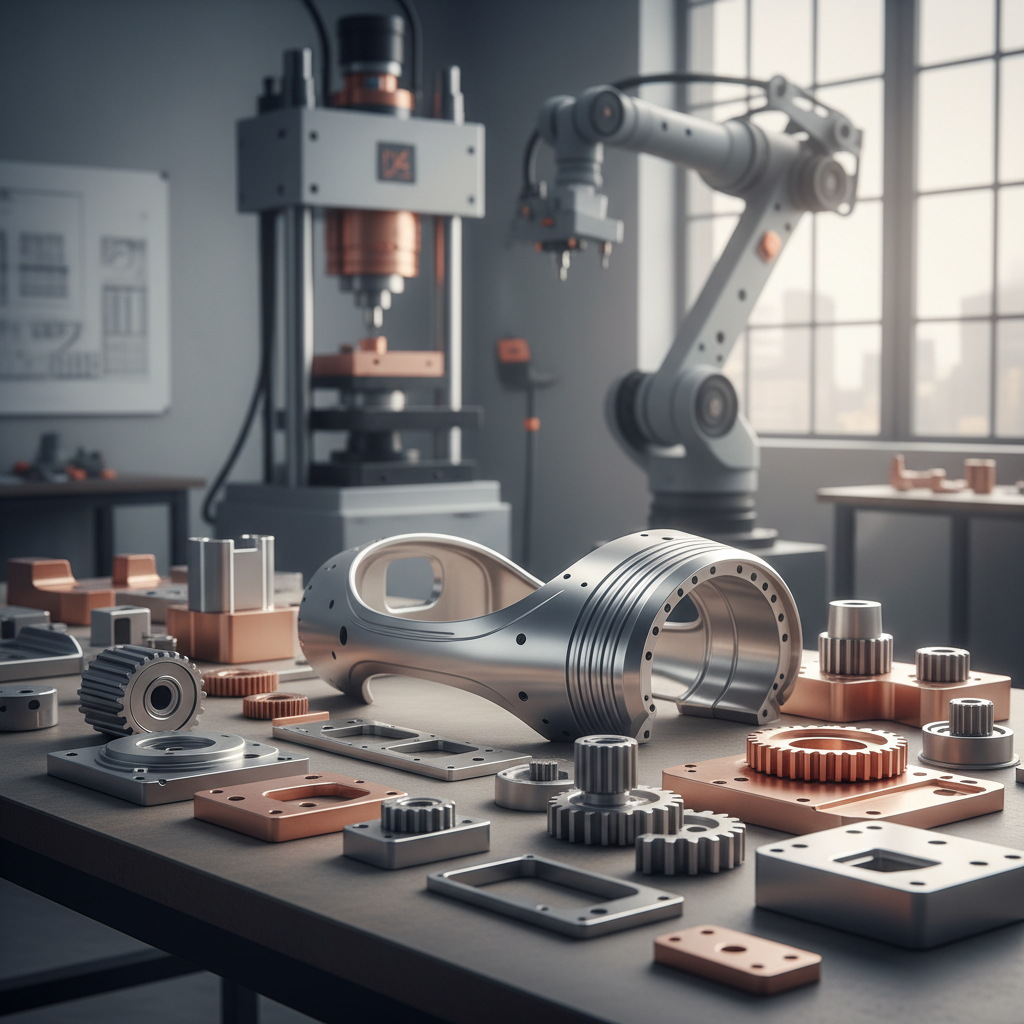

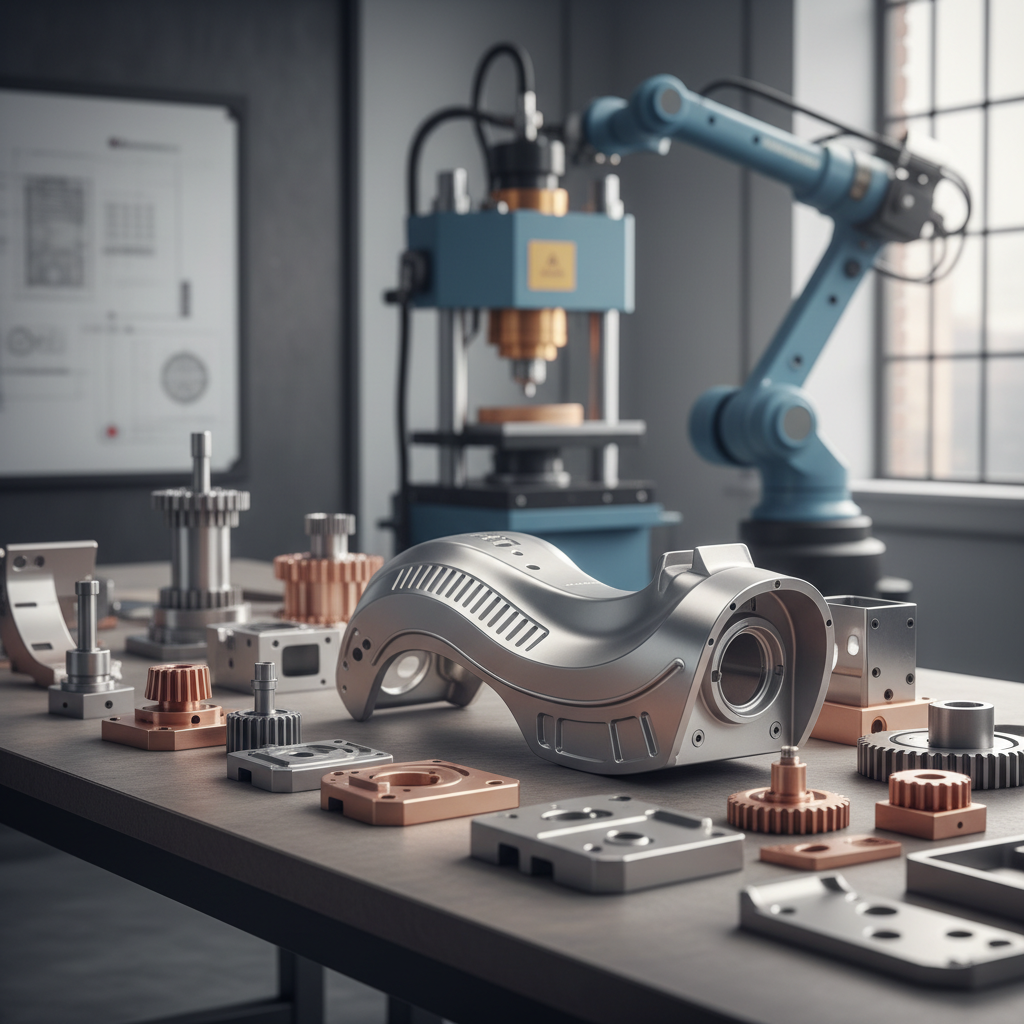

Stamped sheet metal is increasingly recognized for its critical role in enhancing product design and durability. One of the primary benefits is its versatility in forming complex shapes with high precision. This capability allows designers to create innovative products that meet specific functional and aesthetic requirements. The ability to produce intricate designs without sacrificing material integrity opens new avenues for creativity, making stamped sheet metal an ideal choice for various industries, from automotive to electronics.

In addition to design capabilities, stamped sheet metal boasts remarkable strength and durability. The stamping process enhances the metal's mechanical properties, resulting in products that can withstand harsh environments and heavy usage. This durability not only extends the lifespan of the product but also reduces maintenance costs over time. Furthermore, the process is energy-efficient and sustainable, as it minimizes material waste, aligning with modern demands for eco-friendly manufacturing practices. Overall, stamped sheet metal provides a combination of design flexibility and resilience, making it a preferred option for manufacturers aiming to create high-quality, long-lasting products.

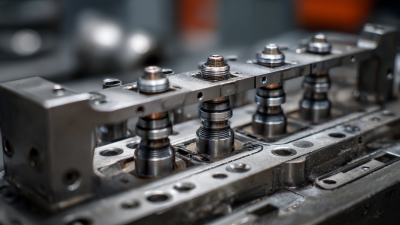

Stamped sheet metal components have gained recognition for their exceptional durability, largely due to several key factors. One of the most significant aspects is the precision manufacturing process involved in stamping. This method ensures that each component is crafted to exact specifications, minimizing discrepancies that can lead to weaknesses in the final product. The consistency and uniformity in thickness achieved during the stamping process contribute greatly to the structural integrity of the components, making them resistant to wear and fatigue over time.

Stamped sheet metal components have gained recognition for their exceptional durability, largely due to several key factors. One of the most significant aspects is the precision manufacturing process involved in stamping. This method ensures that each component is crafted to exact specifications, minimizing discrepancies that can lead to weaknesses in the final product. The consistency and uniformity in thickness achieved during the stamping process contribute greatly to the structural integrity of the components, making them resistant to wear and fatigue over time.

Another crucial factor enhancing the durability of stamped sheet metal is the material selection. High-strength alloys and treatments can be employed to improve resistance to corrosion, deformation, and impact. For instance, galvanization not only protects against rust but also increases the lifespan of the components in harsh environments. Additionally, the ability of stamped components to be designed with intricate shapes and forms allows for the optimization of stress distribution, further enhancing their overall strength and durability. These combined elements make stamped sheet metal a preferred choice for industries demanding reliable and long-lasting performance in their products.

Stamped sheet metal has emerged as a vital material across various industries due to its remarkable versatility and adaptability. In the automotive sector, for instance, manufacturers utilize stamped sheet metal to create lightweight yet durable components that enhance vehicle performance and fuel efficiency. Its strength-to-weight ratio allows for innovative designs that meet stringent safety standards while minimizing environmental impact. Furthermore, the ease of mass production enables the automotive industry to keep pace with evolving consumer demands.

In the electronics and aerospace industries, stamped sheet metal plays a crucial role in producing intricate components that require precision engineering. From housing for delicate electronic devices to structural supports in aircraft, stamped sheet metal ensures reliability and structural integrity. Its ability to be easily molded into complex shapes allows for creative solutions that can streamline assembly processes and reduce manufacturing costs. This adaptability, combined with its resistance to corrosion and high-temperature applications, positions stamped sheet metal as a key player in creating superior designs across multiple domains.

Stamped sheet metal has emerged as a cornerstone in manufacturing, offering a blend of cost-effectiveness and high durability that is hard to match. The process of stamping involves shaping metal sheets into desired forms with precision, which significantly reduces material waste compared to traditional fabrication methods. This efficiency not only lowers production costs but also enhances sustainability, making it an attractive option for manufacturers looking to minimize their environmental footprint.

Additionally, the scalability of stamped sheet metal production allows for large quantities to be produced quickly without sacrificing quality. By employing advanced stamping technologies, manufacturers can achieve high repeatability and consistent results, ensuring that each component meets stringent specifications. This reliability, coupled with the reduced labor and material costs, makes stamped sheet metal an economically advantageous choice that can significantly impact the overall budget of product design and manufacturing processes.

Innovative stamping techniques have revolutionized product design and durability by enhancing performance and reducing manufacturing costs. Advanced methods such as progressive die stamping and servo-driven presses allow for precise control over material deformation. These high-tech processes not only improve the accuracy of complex geometries but also ensure a stronger final product by minimizing material waste. The capabilities of modern stamping technologies enable designers to experiment with intricate designs, ultimately leading to more functional and aesthetically pleasing products.

Additionally, the use of high-strength materials combined with innovative stamping methods results in components that withstand demanding conditions. For instance, lightweight metals can be stamped into robust structures that resist impacts and corrosion, making them ideal for industries like automotive and aerospace. By leveraging these advanced techniques, manufacturers can achieve better energy efficiency and performance while maintaining product longevity. Thus, stamping emerges as a vital component in delivering superior product designs that meet the challenges of modern engineering.