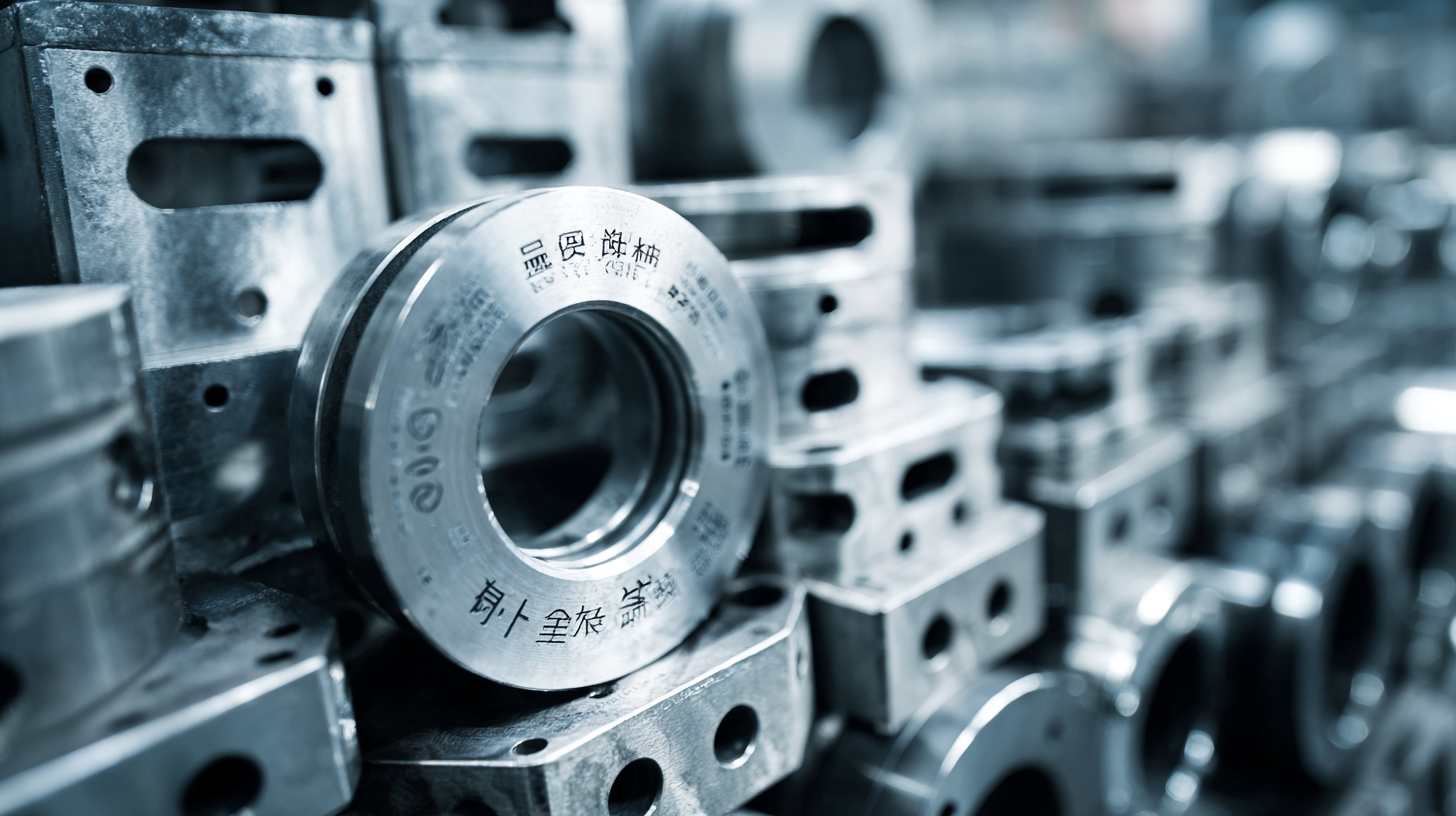

In the rapidly evolving automotive industry, understanding the technical specifications of Automotive Metal Stamping Parts is crucial for manufacturers seeking to enhance their production efficiency and meet stringent quality standards. As we navigate towards 2025, the industry is witnessing significant technological trends that influence the design and functionality of these components. This ultimate guide aims to unravel the complexities of choosing the right automotive metal stamping parts by exploring the critical factors, such as material selection, precision machining, and innovative stamping techniques. By equipping yourself with this knowledge, you can make informed decisions that not only improve the performance of automotive parts but also align with the future demands of sustainability and advanced manufacturing technologies. Embrace the journey of mastering these specifications, as they are integral to driving the automotive sector towards a more sophisticated and efficient future.

When it comes to automotive metal stamping parts, understanding key technical specifications is crucial for ensuring optimal performance and durability. The specifications you should evaluate include material type, precision, thickness, and surface treatment. For instance, studies indicate that steel, due to its strength and cost-effectiveness, dominates the market, accounting for over 60% of automotive metal stampings. Additionally, advancements in high-strength steel (HSS) are paving the way for lighter yet stronger components, addressing the industry's growing sustainability demands.

When it comes to automotive metal stamping parts, understanding key technical specifications is crucial for ensuring optimal performance and durability. The specifications you should evaluate include material type, precision, thickness, and surface treatment. For instance, studies indicate that steel, due to its strength and cost-effectiveness, dominates the market, accounting for over 60% of automotive metal stampings. Additionally, advancements in high-strength steel (HSS) are paving the way for lighter yet stronger components, addressing the industry's growing sustainability demands.

Another critical factor is the precision of the stamping process. According to industry reports, a tolerance level of ±0.1 mm is typically required for automotive applications, which ensures parts fit seamlessly into assemblies and function correctly. Surface treatment is equally important, with processes such as electroplating or coating increasing corrosion resistance, thereby extending the lifespan of automotive components. Having these specifications in mind will empower manufacturers and suppliers to make informed choices, ultimately affecting vehicle safety, performance, and cost-efficiency.

When selecting a manufacturer for metal stamping parts, several crucial factors come into play. One of the foremost considerations is the manufacturer's experience and expertise in the automotive sector. A company that specializes in automotive applications often understands the specific requirements such as precision, durability, and compliance with industry standards. Evaluating the manufacturer's portfolio and track record can provide insight into their capabilities and reliability.

Quality control processes are another vital aspect to consider. Look for manufacturers that employ stringent quality assurance measures, including regular inspections and testing protocols. A commitment to maintaining high quality not only ensures that the parts meet necessary specifications but also enhances overall production efficiency. Lastly, assess the manufacturer’s ability to provide customization and flexibility in production runs, as this can significantly impact your project's timeline and cost-effectiveness. Choosing a manufacturer who is responsive to your unique needs can lead to a more successful partnership in the long run.

The automotive industry is one of the top sectors benefiting significantly from high-quality metal stamping parts. According to a report by Grand View Research, the global automotive stamping market is expected to reach $30 billion by 2025, showcasing a compound annual growth rate (CAGR) of around 4.5%. This growth is driven by the increasing demand for lightweight and fuel-efficient vehicles, necessitating the use of advanced metal stamping techniques to produce components that meet stringent automotive standards. Manufacturers rely on these metal parts not just for structural integrity but also for enhancing vehicle aesthetics and performance.

Another industry reaping the benefits of meticulous metal stamping is the aerospace sector. Data from the Aerospace Industries Association indicates that the aerospace market is projected to reach $1 trillion by 2038, which requires precision-engineered metal stamping solutions. Components such as fuselage parts, cabin interiors, and engine components must adhere to rigorous safety and performance standards, making high-quality stamping crucial. Innovative processes and materials used in metal stamping allow manufacturers to reduce weight while maintaining strength, which is vital for fuel efficiency in both aviation and automotive applications.

| Part Name | Material | Thickness (mm) | Tolerances (mm) | Applications |

|---|---|---|---|---|

| Chassis Bracket | High-Strength Steel | 2.5 | ±0.05 | Automotive Structures |

| Door Panel | Aluminum Alloy | 1.8 | ±0.03 | Vehicle Exterior |

| Control Arm | Carbon Steel | 3.0 | ±0.1 | Suspension Systems |

| Heat Shield | Stainless Steel | 1.2 | ±0.05 | Engine Protection |

| Bumper Reinforcement | Mild Steel | 2.0 | ±0.07 | Impact Absorption |

When it comes to automotive metal stamping, the choice of materials is crucial for both performance and durability. Common materials utilized in this process include steel, aluminum, and various alloys. According to a recent industry report by MarketsandMarkets, the global automotive stamping market is projected to reach USD 59.9 billion by 2026, with steel being the dominant material, making up approximately 70% of the total market share. Steel offers excellent strength, ductility, and cost-effectiveness, making it a preferred choice for various automotive components.

Aluminum, on the other hand, has gained popularity due to its lightweight properties, which contribute to better fuel efficiency. A study by the Aluminum Association indicates that lightweight cars can improve fuel economy by 6-8%, significantly impacting environmental sustainability. However, aluminum can be more expensive, necessitating a careful cost-benefit analysis when selecting materials for specific applications.

**Tip:** When selecting metal stamping materials, consider the specific requirements of your vehicle, such as weight, strength, and resistance to corrosion. Additionally, it's essential to collaborate with suppliers who provide comprehensive material data sheets to ensure the materials meet automotive standards and performance expectations. Always evaluate the long-term implications of material selection on maintenance and lifecycle costs.

In the automotive industry, the quality assurance practices in metal stamping production play a critical role in ensuring the reliability and performance of automotive components. As the sector evolves, manufacturers are increasingly adopting stringent quality control measures throughout the development processes—from initial design to final production. According to a recent report, 70% of automotive failures can be traced back to issues in the manufacturing phase, emphasizing the need for robust quality assurance strategies.

To improve these practices, companies should prioritize standard operating procedures (SOPs) that encompass every phase of the metal stamping process. Implementing a series of checkpoints like A-sample and B-sample evaluations allows for early detection of defects and alignment with technical specifications. This not only minimizes production costs but also enhances product consistency and customer satisfaction.

**Tip:** Regular training for staff on quality assurance methodologies can significantly reduce errors in the stamping process. Furthermore, integrating automated inspection technologies can help maintain high standards of quality throughout production, reducing the likelihood of defects reaching the market.