In the world of hydraulic systems, the integrity and efficiency of operation heavily rely on the use of hydraulic seals. These critical components are designed to prevent the leakage of fluids, maintain pressure, and protect against contaminants, ultimately ensuring the longevity of machinery and equipment. According to John Smith, a renowned expert in the hydraulic seals industry, "The right hydraulic seal can be the difference between machinery that operates flawlessly and one that faces constant repairs."

As industries continue to innovate and evolve, understanding the various types and applications of hydraulic seals becomes paramount. Different environments and operational demands require specific sealing solutions, making it essential for engineers and maintenance professionals to be well-versed in the top options available. This article explores the top 10 hydraulic seals, detailing their unique characteristics and key applications across various sectors, ultimately guiding readers toward optimized performance in hydraulic systems.

From O-rings to rod seals, each type plays a crucial role in the effectiveness of hydraulic machinery, transforming theoretical designs into practical, reliable solutions in the field. By delving deeper into these essential types, we can better appreciate their significance and the impact they have on the success of hydraulic operations.

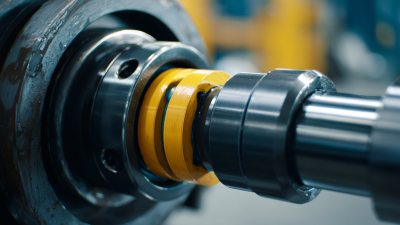

Hydraulic seals play a critical role in ensuring the effective performance of hydraulic systems. To achieve optimal sealing, these components must possess specific characteristics tailored to the demands of their applications. First and foremost, materials used for hydraulic seals must exhibit excellent resistance to temperature variations and chemical exposure. Common materials like nitrile rubber and polyurethane are favored for their durability and flexibility, enabling them to maintain integrity under high pressure and fluctuating temperatures.

Furthermore, the design of hydraulic seals is equally vital. Seals are often engineered to provide a tight fit that prevents leaks while allowing for fluid movement. Factors such as hardness, profile shape, and installation method significantly influence their effectiveness. For example, lip seals are designed to withstand pressure from fluid and keep contaminants out, making them essential for applications in machinery and automotive systems. The combination of material selection and precise design ensures that hydraulic seals perform reliably across various industries, from manufacturing to aerospace, by reducing wear and prolonging system life.

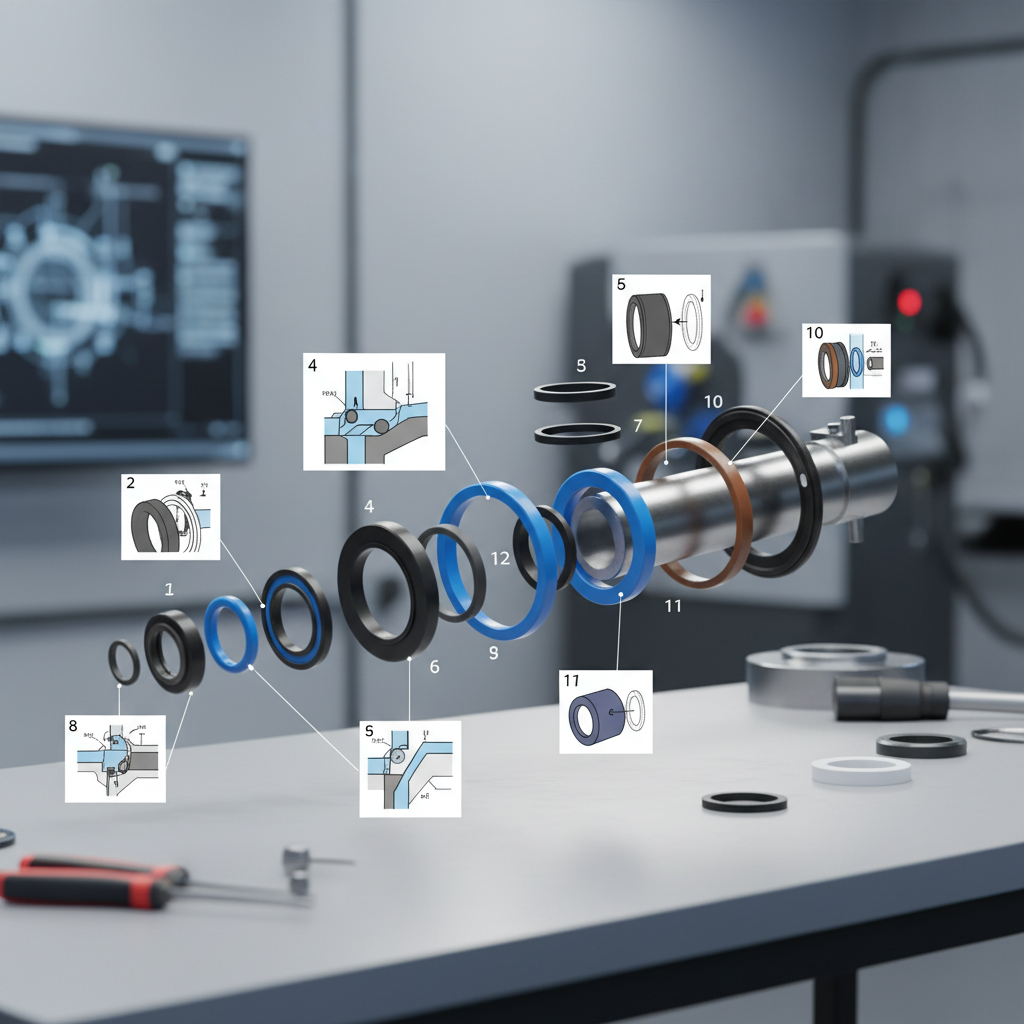

O-rings are a critical component in hydraulic systems, renowned for their versatility and effectiveness in sealing applications. These circular seals are designed to be compressed between two mating surfaces, preventing fluid leaks and maintaining pressure within a system. O-rings are available in various materials, including rubber, silicone, and fluorocarbon, allowing them to perform efficiently in diverse operating conditions. Their adaptability makes them suitable for a wide range of applications, from industrial machinery to automotive systems.

In hydraulic systems, the specific properties of O-rings, such as resistance to high pressure and temperature, play a significant role in their performance. They help ensure the safety and reliability of hydraulic circuits, which are vital in machinery and equipment used in construction, manufacturing, and transportation sectors. The ability to withstand aggressive chemicals and fluids further enhances the applicability of O-rings, making them indispensable in maintaining the integrity of hydraulic operations across different industries. As technology advances, the demand for specialized O-ring formulations continues to grow, driving innovations in material science to improve their functionality and lifespan.

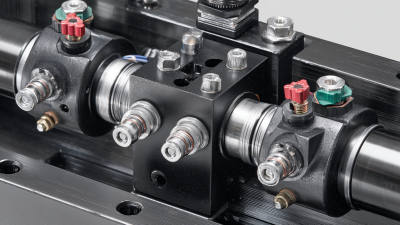

When it comes to hydraulic seals, the market is replete with various types, each designed for specific applications and environments. A comparative analysis of different hydraulic seal types highlights their distinct functionalities and material compositions. For instance, elastomeric seals, such as nitrile rubber (NBR), are commonly used in lower-pressure applications due to their excellent resistance to oils and lubricants. According to the "Global Hydraulic Seals Market Report 2022," elastomeric seals hold a significant share, catering largely to industries like automotive and aerospace, which require reliable sealing solutions.

On the other hand, metallic seals offer superior performance under extreme conditions. These seals, often constructed from materials like stainless steel, withstand higher pressures and temperatures, making them ideal for heavy machinery in industries such as construction and manufacturing. The same report indicates that the demand for metallic seals is expected to rise by 5% annually, driven by technological advancements and the increasing need for durable sealing solutions in hydraulic systems. Additionally, composite seals, which combine the best features of both elastomeric and metallic seals, are gaining popularity in hybrid applications, providing enhanced adaptability and longevity in mixed environments.

The global rubber O-ring market is projected to witness significant growth, expanding from USD 53.54 billion in 2024 to USD 62.34 billion by 2033, with a compound annual growth rate (CAGR) of 1.7%. This growth can be attributed to the increasing demand for advanced sealing solutions across various industries, including automotive and chemical sectors. Among the notable types of O-rings, Perfluoroelastomer (FFKM) and Buna (nitrile) O-rings are gaining traction due to their superior chemical resistance and durability.

Innovative materials in hydraulic seals, particularly in O-ring production, play a crucial role in enhancing performance under harsh conditions. FFKM O-rings, for example, withstand extreme temperatures and aggressive chemicals, making them ideal for specialized applications in the chemical and petrochemical industries. Meanwhile, Buna O-rings are favored for their effective sealing properties in automotive applications, contributing to overall vehicle reliability.

Tips: When selecting O-rings for hydraulic applications, consider the specific operating environment, including temperature fluctuations and chemical exposure, to ensure optimal performance. Regular maintenance and inspection of seals can prevent costly downtime and improve system efficiency.

To ensure the longevity of hydraulic seals, regular maintenance is crucial. One of the most effective practices is to monitor the operating environment closely. Contaminants such as dirt, dust, and debris can significantly compromise seal integrity. Implementing effective filtration systems and maintaining clean hydraulic fluid can dramatically reduce wear and tear on seals.

Additionally, keeping seals lubricated according to manufacturer specifications helps prevent friction and overheating, ensuring smoother operation.

Another important aspect of maintenance is periodic inspections. Regularly checking for signs of wear, such as cracks, grooves, or discoloration, allows for timely replacements and prevents catastrophic failures. Operators should also pay attention to hydraulic fluid levels and quality, as low or degraded fluid can cause hydraulic seals to fail prematurely.

By following these maintenance tips, users can maximize the performance and lifespan of their hydraulic seals, contributing to the overall efficiency of the hydraulic system.