In the evolving landscape of industrial applications, the selection of mechanical seals has become a critical factor in ensuring operational efficiency and minimizing downtime. According to a recent market analysis, the global mechanical seals market is projected to reach approximately $6.2 billion by 2025, driven by the increasing demand across sectors such as oil and gas, chemical processing, and water management. As industries strive for enhanced reliability and sustainability, choosing the right mechanical seals not only contributes to the longevity of equipment but also improves safety and cost-effectiveness.

This guide aims to provide comprehensive insights and practical advice for selecting the best mechanical seals tailored to your specific industry needs, empowering you to make informed decisions that align with the latest market trends and technological advancements.

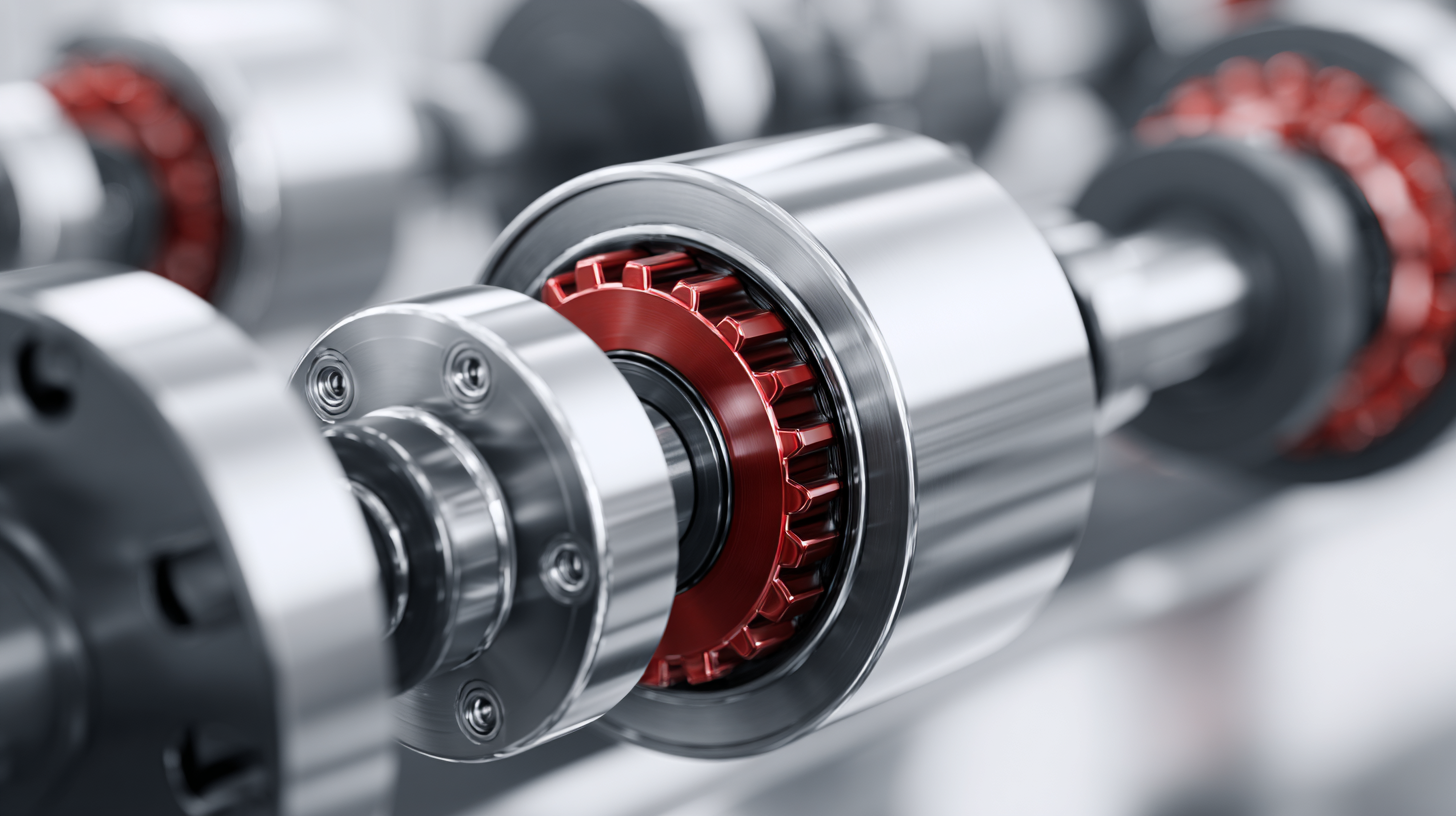

When selecting mechanical seals for industrial applications, it is crucial to consider the specific needs of your industry. Factors such as the chemical compatibility of materials, the operating temperature range, and the environmental conditions can greatly influence the performance and longevity of mechanical seals. For instance, stainless steel corrugated seals are often favored for their durability in high-pressure environments, while high nickel alloy seals excel in corrosive conditions, ensuring reliability and efficiency.

Tips: Always analyze the specific applications and conditions to determine the appropriate seal type. For high vacuum seals or zero-leak motion feeders, the design of the seal must accommodate dynamic movements while maintaining tightness. Another crucial consideration is the flexibility of joints; it allows for thermal expansion and contraction, which can help maintain the integrity of the sealing system over time.

The global market for cable sealing solutions is also evolving, with increasing demand across telecom and energy sectors. Selection of the right sealing solution, whether mechanical or chemical seals, plays a pivotal role in maintaining performance under various installation methods. Ensure to keep up with trends in materials, like plastic and rubber seals, to optimize performance while adhering to industry standards.

When it comes to selecting the right mechanical seal for your application, understanding the various types and their respective advantages and disadvantages is crucial. Common types of mechanical seals include single seals, double seals, and cartridge seals. Single seals are cost-effective and simple in design, making them ideal for many standard applications. However, they can be less effective in handling high-pressure environments or corrosive fluids, which may lead to leaks.

On the other hand, double seals offer enhanced reliability and are particularly suited for high-risk applications where leakage can pose significant hazards. They effectively create a secondary barrier, which can be indispensable in volatile industries such as oil and gas. Nevertheless, the complexity of double seals often leads to higher installation and maintenance costs, which should be carefully considered. Cartridge seals, meanwhile, simplify installation and maintain alignment effectively, but may not be suitable for all environments due to potential limitations in pressure and temperature tolerances. By weighing these pros and cons, industries can make informed decisions that enhance operational safety and efficiency.

When selecting mechanical seals for your industry needs, understanding material compatibility is crucial. The right material can significantly enhance seal performance and lifespan. Different applications require specific materials that can withstand varying levels of temperature, pressure, and chemical exposure. For instance, if your application involves aggressive chemicals, materials like PTFE or ceramic may be ideal due to their resistance to corrosion and wear.

Tip 1: Always conduct a compatibility analysis between the seal material and the substances it will encounter. Many manufacturers provide material datasheets that detail chemical resistance, which can guide you toward the most suitable options.

Moreover, consider the environment where the mechanical seals will operate. Factors such as humidity, temperature fluctuations, and exposure to abrasive particles can dictate material choice. Using elastomers designed for high temperatures might be necessary for heat-intensive operations, while softer materials may work better in lower-stress situations.

Tip 2: Consult with your seal supplier about their recommendations based on your specific application conditions. They often have extensive experience and can offer valuable insights on material selection.

Overall, paying careful attention to material compatibility not only ensures efficient performance but also minimizes operational disruptions, saving time and costs in the long run.

When selecting mechanical seals for your industry, evaluating the reputation and quality of manufacturers is paramount. According to a market analysis by Grand View Research, the mechanical seal market is expected to reach USD 6.49 billion by 2025, indicating a burgeoning demand and a variety of manufacturers vying for attention. Quality and reliability are essential because a substandard seal can lead to costly downtime and environmental hazards.

Tip: Look for manufacturers with ISO certifications and those that comply with industry standards like API or ASTM. These certifications are indicators of a manufacturer's commitment to quality and reliability.

Additionally, customer reviews and case studies can provide insight into a manufacturer's performance. Researching industry reports and client testimonials will help reveal the track record of a seal manufacturer. A survey by B2B International shows that 74% of engineers rely on online reviews to evaluate suppliers, making discernment of genuine feedback critical.

Tip: Reach out to peers in your industry and consult platforms like LinkedIn to gauge the reputation of potential suppliers. Networking within your field can lead to valuable recommendations and firsthand experiences that will support your decision-making process.

When it comes to selecting mechanical seals for various industries, understanding the landscape of leading brands is crucial. The mechanical seal market, particularly within the oil and gas sector, has shown significant growth, with projections indicating an increase from approximately $2.67 billion in 2023 to $3.56 billion by 2032. This growth is fueled by advancements in seal technology and an increasing focus on efficiency and reliability in harsh environments.

A comparative analysis of prominent mechanical seal brands reveals their unique strengths and applications. For instance, the carbon floating ring seals, widely utilized in industrial and marine applications, depend on materials such as carbon fiber and graphite to enhance performance under extreme conditions. Different brands prioritize specific features like durability, ease of installation, or adaptability to various operational challenges, making it essential for industries to evaluate their specific needs against available options in the market. The diversity in seal sizes and compositions, ranging from small (under 100 mm) to medium (100-250 mm), further complicates the decision-making process but also presents opportunities for tailor-made solutions.